BombThreat

'Diggity

- Location

- Johnstown, NY

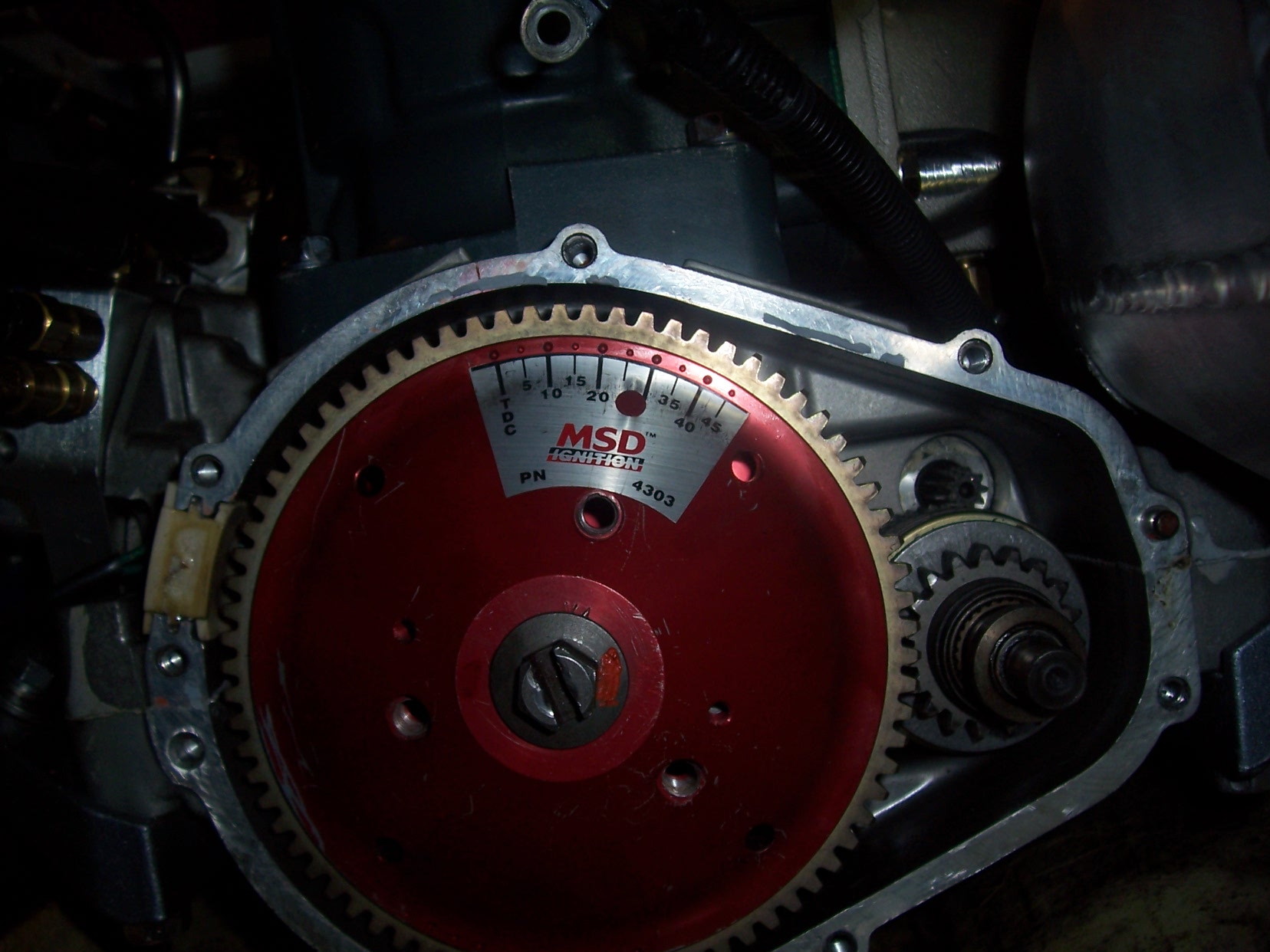

I have been dragging my feet with this thing since I've been waiting for some compression domes to be cut... We'll their coming finnaly! So now im syched and want my ski ready for the weekend. I spoke with Paul at LPW and with my setup he recommended 14 static and 30 overall timing. And to tell you the truth I dont have a clue on how to set it! I'm including a picture of my flywheel if you guys could edit it and show me where to turn things, ect... That would be so awesome:brap: