You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Super Jet Is nozzle boring worth it?

- Thread starter kylemx19

- Start date

D-Roc

I forgot!

- Location

- Dirty River Rider

Lmao

I run a oem 155 pump with modified Tbm pump stuffer. It was cheaper than any mag pump and I would not trade it for any pump setup that is smaller. No 144 mag can put down power like a 148 or 155 pump. No Internet cowboy can tell you the best prop for your ski. Do yourself a favor and visit skat-trak website. They make props that work. Check out their application chart and get an idea of what they have tested to work on what ski with what size motor and what size pump. Then pick a prop and tune it in like I said.

http://skat-trak.com/watercraft.html

Or, listen to how many people will tell you what prop to run. It's hilarious.

I run a oem 155 pump with modified Tbm pump stuffer. It was cheaper than any mag pump and I would not trade it for any pump setup that is smaller. No 144 mag can put down power like a 148 or 155 pump. No Internet cowboy can tell you the best prop for your ski. Do yourself a favor and visit skat-trak website. They make props that work. Check out their application chart and get an idea of what they have tested to work on what ski with what size motor and what size pump. Then pick a prop and tune it in like I said.

http://skat-trak.com/watercraft.html

Or, listen to how many people will tell you what prop to run. It's hilarious.

He is right, Figuring your pump set-up is expensive thats why a lot of guys just run what the next guy is running You can use the Cowboys suggestions as a starting point, Thats what I did and I still went thru 4 impellers, a bored nozzle and a stubby cone...Lmao

I run a oem 155 pump with modified Tbm pump stuffer. It was cheaper than any mag pump and I would not trade it for any pump setup that is smaller. No 144 mag can put down power like a 148 or 155 pump. No Internet cowboy can tell you the best prop for your ski. Do yourself a favor and visit skat-trak website. They make props that work. Check out their application chart and get an idea of what they have tested to work on what ski with what size motor and what size pump. Then pick a prop and tune it in like I said.

http://skat-trak.com/watercraft.html

Or, listen to how many people will tell you what prop to run. It's hilarious.

- Location

- Crystal River, FL

It does make a lot of sense what D-Roc is saying.

Instead of me listening to the normal opinion that everyone has, I am trying to gather all of the info that I can.

I do agree with how a 155mm pump will put out more than a 144.

I will look at the skat website and I'm sure I'll have a few more questions for you guys.

I greatly appreciate all the info from you all so far.

Instead of me listening to the normal opinion that everyone has, I am trying to gather all of the info that I can.

I do agree with how a 155mm pump will put out more than a 144.

I will look at the skat website and I'm sure I'll have a few more questions for you guys.

I greatly appreciate all the info from you all so far.

Dave exchanges props too....so if you don't like 13/16-3 then you could change it.

Daves opinion is gold IMO. Impeller pros=IMPROS!

When did he start doing that? When I was swapping impellers he wouldn't....

OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

Sure he'll do it, no problem. You won't like the exchange price though. Last couple I discussed with him and all he was offering was $80 per.

ya I went from a 9/15->11/17->10/16->13/17 sold every one here on the x

Were any of them cut back? Which one did you like best?

I dont remember, I was running an XM771 and honestly didnt notice much difference between the 10/16 and 11/17 ski didnt have much pop but that 11/17 is the fastest I've ever gone on a ski, I ended up with the 13/17, Bored nozzle to 85 taper and stock cone, tied the stubby and didnt find any gains but oddly enough with the stubby in my carbs brought out an issue in my carbs...like it was rich swapped the stock cone in and was satisfied...took 2 months of screwing around and I hit harder then another guys 865

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

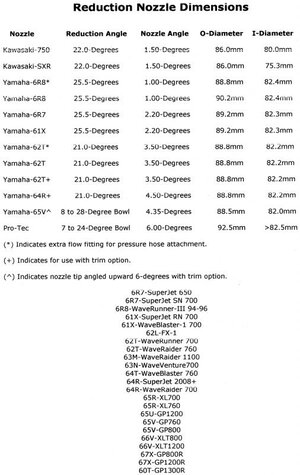

The basic reduction nozzle rules are; the larger the nozzle exit diameter, the greater the volume of water you can move. This is great for a freestyle bottom end and hole shots but the problem is that sometimes you do not have the proper exit velocity for top speed. The smaller the nozzle exit diameter, the greater the velocity of the water exiting, the better the top speed. The problem is that sometimes there is not enough volume of water to get the ski to top speed. It takes a blend of the two that gets both hole shot and top speed. If you have two different exit sizes or angles to compare, then one is more than likely better than the other and it takes testing to find out what works best with your setup. All the nozzles have a tapered exit angle and it is NOT recommended to bore them straight because it loses pump efficiency so the angle should be maintained if boring your nozzle. Each reduction nozzle that Yamaha develops is specifically engineered for their skis by the engine power to weight ratio, pump size, impeller type & pitch, hull design, top speed, drag etc. Most of their jet-ski's with smaller displacement engines that weigh less use the steeper 25.5-degree reduction nozzle angles with varying nozzle exit tip angles. While the bigger ski's that weigh more with the larger engine displacements use the 21-degree reduction nozzle angle with different nozzle exit angles and sizes. Some of their nozzles even use a bowl shape design with the nozzle exit angled upwards. Your hull can travel at radically different angles at different speeds depending on your ride plate, venturi angle and even how you're positioned on the ski. The steeper nozzle exit angles of 3.5-degrees or more will lighten the nose of the craft and may add top speed. While the shallower nozzle exit angles of 2.5-degrees or less will deliver improved performance in rough water conditions by producing more nose pressure to drive the hull through the bumps which is perfect for closed coarse and offshore competition race boats. Also a ski traveling at an angle of 2-degrees does not bring in the same amount of water into the intake tunnel as a ski traveling at 5-degrees at real high speeds. The faster the ski travels the greater its tendency to run flatter and use a smaller venturi. If you continue to try to run at 5-degrees, then you're going to run into the pump over stuffing problem and a bigger diameter venturi may be just what you need to process that extra volume of water coming into the intake. All these things need to be taken into consideration when using other reduction nozzles types with different angles and exit diameters.

Here's a chart to see all the different angles and dimensions of the reduction nozzles.

Here's a chart to see all the different angles and dimensions of the reduction nozzles.

Attachments

I ended up with the 13/17, Bored nozzle to 85 taper and stock cone,

Golden! I couldn't use a stubby with that set up either.

- Location

- Crystal River, FL

MADMAT,

What setup was your final decision, and why?

What setup was your final decision, and why?

I can take zero credit for my decision...I called Dave 5 years ago or more and said, "dude I need it to pull really hard and I can care less how fast it goes. I have a B pipe, a 710cc, and a MSD, and like 195psi."

He said OK here is what you want I bolted it on and was like hell yea! I had went from a craaaaaaaaap 14.5/18.5 (or 19 can't remember!) skat to this. Then I tried the 85mm nozzle and clearly felt more pull. Then I tried the pump cone and it sucked. Then pump cone with stock 80mm nozzle and it was better but sucked compared to the pop of the stock cone with 85mm nozzle. I tried all of these parts several times on at least 2 ski to be sure.

No I'm at 718cc and same everything and it still pulls up the face of waves perectly! Pulls you up fast and goes 48mph (GPS'd it a freeride once) which is plenty for my spot.

He said OK here is what you want I bolted it on and was like hell yea! I had went from a craaaaaaaaap 14.5/18.5 (or 19 can't remember!) skat to this. Then I tried the 85mm nozzle and clearly felt more pull. Then I tried the pump cone and it sucked. Then pump cone with stock 80mm nozzle and it was better but sucked compared to the pop of the stock cone with 85mm nozzle. I tried all of these parts several times on at least 2 ski to be sure.

No I'm at 718cc and same everything and it still pulls up the face of waves perectly! Pulls you up fast and goes 48mph (GPS'd it a freeride once) which is plenty for my spot.

Last edited:

- Location

- Crystal River, FL

I'm gonna have to steal it from you now.

What exactly did he tell you to get?

What exactly did he tell you to get?

D-Roc

I forgot!

- Location

- Dirty River Rider

A lot of skis don't have the pump setup to the best it could be for the motor they are running. This is for many different reasons though.

Hey zero that is some great info. What are your thoughts on the fins in the reduction nozzle. Seems to me It's the difference between a tight or wide spread jet blast. I like to have the wider spread but it is a difference in stability. It seems to get the push of the blast happening quicker. It makes turns different so I ended up using the aluminum fx140 turn nozzle. Which makes again, noticeable change in the skis tracking. I like it better than one without the little fins.

I ran a 13/16 -3 cutback Solas and it is a good prop with limited engine mods, and stock pump. I liked the c75 12/17 big hub skat better. The Solas works really good when the ski is moving. The skat I could get to yank right off idle but used the Tbm pump stuffer with shortest cone and 84 mm reduction nozzle to do it. If your not running a big bore motor then I have seen guys run it at 87 mm to keep the motor snappy. No slipping of the prop either. And if it did you could put a bigger tail cone in. Boring is so final, lol you can't go back.

Hey zero that is some great info. What are your thoughts on the fins in the reduction nozzle. Seems to me It's the difference between a tight or wide spread jet blast. I like to have the wider spread but it is a difference in stability. It seems to get the push of the blast happening quicker. It makes turns different so I ended up using the aluminum fx140 turn nozzle. Which makes again, noticeable change in the skis tracking. I like it better than one without the little fins.

I ran a 13/16 -3 cutback Solas and it is a good prop with limited engine mods, and stock pump. I liked the c75 12/17 big hub skat better. The Solas works really good when the ski is moving. The skat I could get to yank right off idle but used the Tbm pump stuffer with shortest cone and 84 mm reduction nozzle to do it. If your not running a big bore motor then I have seen guys run it at 87 mm to keep the motor snappy. No slipping of the prop either. And if it did you could put a bigger tail cone in. Boring is so final, lol you can't go back.

I'm gonna have to steal it from you now.

What exactly did he tell you to get?

Solas 13/16-3mm ......then once I got it I saw it was a 13/17 repitched to 13/16 on the paperwork.

I have always wondered about the c75 12/17 big hub though.