I was post ride flushing my ski and happen to notice water leaking from where the circlip/ barb end of the FCV valve that allows the body to rotate for adjustment. I disassembled the valve, checked the jet wasn’t clogged (PFP pipe) and noticed the barb is made with a plate that is pushed thru the main body of the valve, that the big end of the spring seats against and circlipped so it can spin. What seals the barb/ plate to the body? Is leakage normal ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jetworks FCV Leakage

- Thread starter mikesx

- Start date

@mikesx how long had you had the FCV? curious if your oring was missing or just damaged as well.

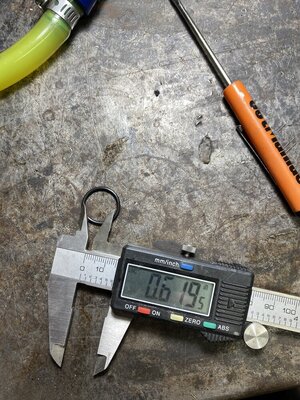

My FCV has about 20 gals. ride time on it. I did disassemble it and found both orings were perfect. I'm pretty sure I know why it was leaking. I had it adjusted as loose as possible, easiest opening for my test ride. If you look at Harbors 3rd pic you see the piece that gets the circlip to hold it in the adjusting body. That oring seals on a surface in the id of the adjusting body. That sealing surface is only 1/16-3/32 wide. The circlip only "holds" the piece in the body. When adjusted loose hose tension can deflect it allowing it to leak.

The face of that piece is also the seat for the check/ball spring. I guess it was designed to have a certain minimum spring pressure on it to hold it pressed into the very end of the adjusting body. I actually air tested from the circlip end and it would hold 10#'s fine, till you wiggled it.

Last edited:

I finally got adjustment under control. What temps are you shooting for? I’m measuring with a Fluke noncontact, right on the metal at the inlet coupler. I’ve got it dialed to the point of 1/2 turn in, up 10 degrees, 1/2 turn out, down 10. 898 Pv motor, PFP dry, PFP Box, Novi 48’s Maxx 155 .....

I assume your talking water box temp ?

I adjust mine by how the ski responds to each adjustment. I do monitor the temp on top the box with a temp strip. I liked the throttle response of a more loosely set Fcv on mine. Roughly 65 deg lake water and 130 deg ish water box, on top the box.

I found the adjustment to be opposite of what I was expecting.. I thought a tightly adjusted FCV was better.

I adjust mine by how the ski responds to each adjustment. I do monitor the temp on top the box with a temp strip. I liked the throttle response of a more loosely set Fcv on mine. Roughly 65 deg lake water and 130 deg ish water box, on top the box.

I found the adjustment to be opposite of what I was expecting.. I thought a tightly adjusted FCV was better.

Attachments

Yes water box temp. The tighter the valve higher the temp. Less water later. Loosely more water earlier, more back pressure I assume?I assume your talking water box temp ?

I adjust mine by how the ski responds to each adjustment. I do monitor the temp on top the box with a temp strip. I liked the throttle response of a more loosely set Fcv on mine. Roughly 65 deg lake water and 130 deg ish water box, on top the box.

I found the adjustment to be opposite of what I was expecting.. I thought a tightly adjusted FCV was better.

Sounds reasonable…. I should of said, I was running an RRP wet pipe before the Pf pipe…I like the RRP dry and hot fir more top end and less jerk during throttle blipping… So when I added the pf, I tried it as received new, then cranked in the fc, then tightened it more, then loosened it, then loosened it more, I liked more water over less water on the pf…