Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

Now your getting tupid.Does the motor want to twist on the motor mounts? Am I better to align the mid shaft dead center or up and to the right?

LOL Just remember what they say about payback.

Now your getting tupid.Does the motor want to twist on the motor mounts? Am I better to align the mid shaft dead center or up and to the right?

Does the motor want to twist on the motor mounts? Am I better to align the mid shaft dead center or up and to the right?

Thanks for proving my point. It's not that complicated. 100% agree lol.

Rewind last week (someone go find the link) some dude on Facebook post a video using a CF alligment tool and it's dead nuts centered but once he rotates the shaft it's off (maybe ten to twenty thou) it enters into the hole with mild force but doesn't slip in like a 16yr old on prome night. I state the drive line moves more than than in a dynamic state, as does the hull flex more than that alligment was off. All though likely the shaft itself had run out issues it was only a 701 setup. Everyone was like rip the pump out and buy a new shaft. You got to be fcking kidding me, it's a 701. It might matter on a 1200Ninja but now the poor guy probably went out and spent a few hundred to make something that was allready in spec even better. Nothing wrong with that but c'mon.

Then this thread surfaces mocking the "bad" Facebook advice. It's not until you over complicate things until you realize it doesn't matter.

What's bad advice? I guess it depends on ones wallet

Thanks for proving my point. It's not that complicated. 100% agree lol.

Rewind last week (someone go find the link) some dude on Facebook post a video using a CF alligment tool and it's dead nuts centered but once he rotates the shaft it's off (maybe ten to twenty thou) it enters into the hole with mild force but doesn't slip in like a 16yr old on prome night. I state the drive line moves more than than in a dynamic state, as does the hull flex more than that alligment was off. All though likely the shaft itself had run out issues it was only a 701 setup. Everyone was like rip the pump out and buy a new shaft. You got to be fcking kidding me, it's a 701. It might matter on a 1200Ninja but now the poor guy probably went out and spent a few hundred to make something that was allready in spec even better. Nothing wrong with that but c'mon.

Then this thread surfaces mocking the "bad" Facebook advice. It's not until you over complicate things until you realize it doesn't matter.

What's bad advice? I guess it depends on ones wallet

Ok who is setting up a go fund me account? How much do I need to contribute to learn how to use dial indicators on fiberglass hulls and aluminum cases to align the various shafts? Will they just be emailed to those who pay or will they be stickered in a sort of technical library here?

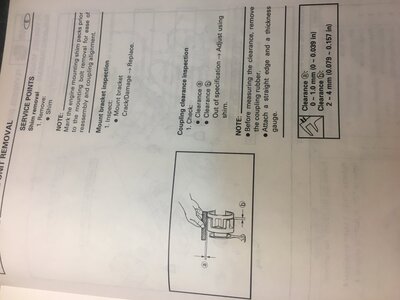

Oh yeah. I have that Yamaha Super Jet Service Manual too. Vague to me for sure. I don't even know how you can get a visual on the straight edge when the engine is in the hull, much less measure the "a" gap. If some one knows how to do this, please explain.

Bottom line: There is knowledge about standup jet skis which is disappearing daily. The skis last 25 years or more and are being resurrected by people like me who are clueless and have to reinvent the wheel and re-ask stupid questions daily. While those with the accumulated knowledge to really build them right are leaving the sport or are leaving the planet daily.

For example, SuperTune was "Last seen Nov 13, 2012" To me his posts are golden, but learning from a post here and there is like looking at a pages 25, 71, 201 in a book of his mind which is 20,000 pages long. I would love it if we could encourage him and Jr. and other greats in the 2-cycle part of our sport to put their Biblical knowledge on paper here.

I saw that thread, i agree its was the right thing to change it! Do you own that CF tool? I dont!

Its a tool for people that dont know correct alignment! I use V blocks and dial indicators on every shaft Before assmbly! What a total waste of time to go thru full assmbly and stick it in a hull to find out your screwed!

The problem is what is acceptable / good enough vs correct?? I prefer to do it correct, espically if a client is paying for it! Pleant of crap shops doing crap work! Sorry, not playing that game. Im actually surprised in your profession your stating something like that is acceptable?

Just curious what kind of acceptable run-out range you would use for rating the condition of set back mag pump driveshafts? Thanks in advance. I'm just looking for some info on this as I have seen a few that were less than perfect.

DAG and Jr. should line up their T1's and have a good old fashioned flip off.

Perfect. thanks. I know the one turning the prop in my ski is not perfect and when I have time i am interested to see how far off it is. Just from my perspective it runs fairly smooth, about the same as it did when I had stock pump. probably my saving grace is the heavier construction of the set back driveshaftI try to hold it .005” - .010” TIR Most say .015- .020” is fine? Most setback shafts are heavier compaired to SJ thinned shafts, thus have less tendency to “whip” at speed. Reguardless, runout equals vibration, the truer the better.

Is that what your looking for?

He needs to bring it to the surf then! Im pretty sure my flat water flipping days are about over!

Looser buys the “Ritas”!

I think pauly still owes me a few. **Don’t make me pull out the ole 701 vs TPE pic I have