You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lengthening hull

- Thread starter yamanube

- Start date

I don't think that will result in the ride I want, the hull area behind the engine assembly is SO much shorter than most any other hull which results in the rider weight being pretty far behind the center of mass or the center of the riding surface. The long plate kind of addresses this but bulkhead back to the end of the hull is something like 10" or more shorter than a superjet (just for reference) and I think having the intake tract and steering pivot that close to the center of the hull might be undesirable. I am thinking about pulling the short driveshaft out of my pump, putting a superjet length driveshaft in, then moving the entire pump assembly and intake tract back that much.

It's not like I am chopping up a big money carbon KDX, this hull has a current market value of $1700.

http://www.x-h2o.com/index.php?threads/fs-max-bun-pro-ufo-fiberglass-hull-1700.192853/

Im actually on board with this idea! Here is my 2 cents. The one key element you need to keep in mind is the hull needs to balance once the stretch is completed! You need to have a 3-5 degree angle of attack to the water surface when on plane. The idea your presenting in the Sj length driveshaft is probably what you want?? In the photo I have attached, is this your hull bottom?? If I remember these hulls correctly, the short shaft they use was shortened 6-8” ?? Is that about right? I have a line drawn to where I suggest cutting. This point will be just inside the tray, behind the firewall. But try to stay forward of the pump tunnel. I agree, a crap load of work! But you will probably have a very unique riding hull when completed!,

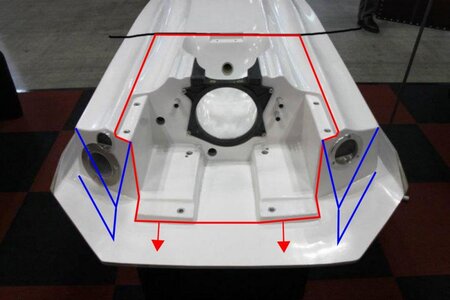

I was actually thinking something very similar but sectioning out just the pump area (red) and shifting that back, then exhaggerating the angled portion on the rear (blue), leaving as much of the hull structure in tact as possible, reducing the chances of breakage and hopefully lessening the amount of technical body work and grafting.Im actually on board with this idea! Here is my 2 cents. The one key element you need to keep in mind is the hull needs to balance once the stretch is completed! You need to have a 3-5 degree angle of attack to the water surface when on plane. The idea your presenting in the Sj length driveshaft is probably what you want?? In the photo I have attached, is this your hull bottom?? If I remember these hulls correctly, the short shaft they use was shortened 6-8” ?? Is that about right? I have a line drawn to where I suggest cutting. This point will be just inside the tray, behind the firewall. But try to stay forward of the pump tunnel. I agree, a crap load of work! But you will probably have a very unique riding hull when completed!,

Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

Go for it!

If someone thinks this is a horrible idea, feel free to give me $2400 and save this hull.

I have always enjoyed encouraging people with their stupid ideas.........

But seriously, I see where your going by just cutting out the pump pocket and pulling it back. You will also need to extend the outside strakes to match . I think my idea will be less work in the long run, but need to come up with some sort of stringer to give the longitital support as is your concern. Keep thinking it thru, your on the right path, if your serious to do this.

CD155MX

Squirrel!!!

- Location

- Alta Loma, CA

Half of you "go for it's" in here just want to watch the world burn. The other half are really helpful. Not sure where I land just yet.

Subscribed anyway. This will be fun to watch.

Subscribed anyway. This will be fun to watch.

Last edited:

I have a maxx hul and both rideplates (long and short) the difrens metween the 2 is night and day, with the short one 360s comes around but landings all croked flips the back off my head hits the water. With the long one setup wakes get bigger and recovery is mush better, i am 193 cm and a 100 kg soo not a small guy. My 02 cent is try the long one before you cut it up, if you make a full with ride plate i am in for one

tom21

havin fun

- Location

- clearwater FL

JR has it right imo. its the reverse of the grafting a 144 tunnel into an fx. The hours of cutting, grinding and itching aside the toughest part of this is alignment. don't forget you have to cut out the tray to have access to put it all back together. Heres another crazy way to go, just cut right straight thru entire hull. there are 2 upsides to this. 1 is alignment will be easier and 2 is the gunwhales will be where you would expect them. glass in bottom and sides with tray out. then repair inside gunwhales and tray.

- Location

- Saskatchewan

This sounds like way too much work to me but I'm definetly sub'd! Love seeing work like this complete. My thoughts are the time spent doing this could be time spent working and saving up for the exact hull you want instead of potentially making something that doesnt turn out to ride as you imagined.

Would be bummed to spend all that time to find out it wasnt what you imagined and now you've got a hull that's even harder to sell.

Would be bummed to spend all that time to find out it wasnt what you imagined and now you've got a hull that's even harder to sell.

Would be bummed to spend all that time to find out it wasnt what you imagined and now you've got a hull that's even harder to sell.

Jason, if she rides bad after the surgery just lie and say it was the best decision you’ve made

Jk, subbed

Yamanude (JR has it right imo. its the reverse of the grafting a 144 tunnel into an fx. The hours of cutting, grinding and itching aside the toughest part of this is alignment. don't forget you have to cut out the tray to have access to put it all back together. Heres another crazy way to go, just cut right straight thru entire hull. there are 2 upsides to this. 1 is alignment will be easier and 2 is the gunwhales will be where you would expect them. glass in bottom and sides with tray out. then repair inside gunwhales and tray.

I have a superjet for that, this is just for fun.This sounds like way too much work to me but I'm definetly sub'd! Love seeing work like this complete. My thoughts are the time spent doing this could be time spent working and saving up for the exact hull you want instead of potentially making something that doesnt turn out to ride as you imagined.

Would be bummed to spend all that time to find out it wasnt what you imagined and now you've got a hull that's even harder to sell.

- Location

- La Crosse, WI on the BIG River

I have a maxx hul and both rideplates (long and short) the difrens metween the 2 is night and day, with the short one 360s comes around but landings all croked flips the back off my head hits the water. With the long one setup wakes get bigger and recovery is mush better, i am 193 cm and a 100 kg soo not a small guy. My 02 cent is try the long one before you cut it up, if you make a full with ride plate i am in for one

So you're 220lbs 6'4". I'll have the liter of cola....

yes correctSo you're 220lbs 6'4". I'll have the liter of cola....

Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

Viagra?

That reference took a google search to figure out, which makes me feel young.Viagra?