After a Very Successful Test Period and Daytona Freeride Debut, I'm now offering the MS01 CDI for Pre-Sale. Expected Early March delivery date.

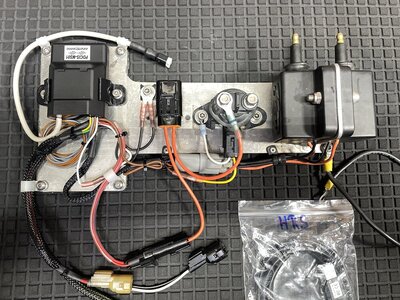

CDI will come, MS01 CDI Brain, Programing Cable & Software, Pre-Assembled Duetsch connectors , and mounting Bracket. List will be $650.00 USD.

Special Introductory Pre-Sale pricing is $600.00 USD until end of January 2024, 50% deposit required to lock in this price.

Hall Sensor Upgrade package will include (2) Hall Sensors, (2) Mounting Blocks, 62T Case plug, Duetsch Connector, Hardware $149.95USD

Please Email all MS01 Pre-Sale inquiries to paul@lehrperformance.com

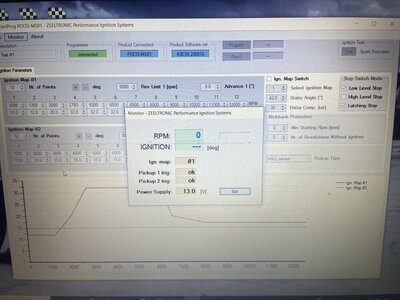

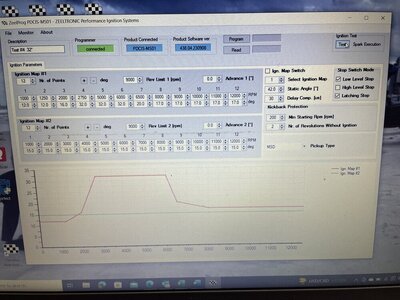

I have worked closely with Zeeltronics over the past 15 - 16 months to develop a MSD 42351 replacement option. That option is nearing completion of testing.

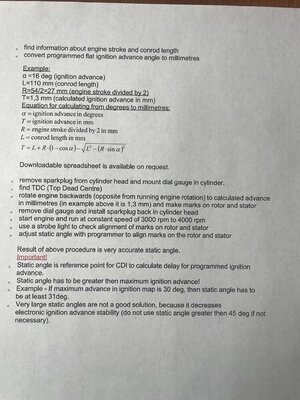

I would like to present the Zeeltronic MS01 TL CDI This is a Fully Programable, Two Channel, switch on the Fly CDI, offering High Spark output, Kick-Back Starting protection , Utilizing MSD 42351 components. Option to run Std MSD triggers, Or Hall Sensors.

MS01 will be offered Exclusively Thru LPW. Demonstrations and display will be at Daytona Freeride 1/11-14. Demonstration’s will be at Flatwater Fri / Lake Diaz, and static display Vendors Alley/ Saturday at the HardRock. Come see what this New TL Ignition option can do!

Last edited: