- Location

- Texas

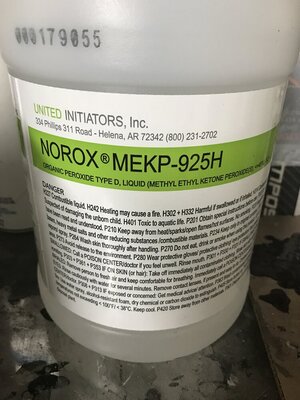

Those who work with Vinylesther Resin and Poyesther Resin, have you noticed a shortage of MEK? A lot of places are sold out or the prices have gone up a bunch.

For reference, the Kommander and Bullet Hulls are made with Vinylesther. Mister Ho Hulls are made with Polyesther Resin.

I do all my repairs with Epoxy Resin (no MEK needed) anyway, but was contemplating making a cheap Prototype Hull with Poly Resin.

FYI MEKP is made from Raffinate, an Oil Derivative...

For reference, the Kommander and Bullet Hulls are made with Vinylesther. Mister Ho Hulls are made with Polyesther Resin.

I do all my repairs with Epoxy Resin (no MEK needed) anyway, but was contemplating making a cheap Prototype Hull with Poly Resin.

FYI MEKP is made from Raffinate, an Oil Derivative...