You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SXR Milling head

- Thread starter sxrchris

- Start date

- Location

- the jetski grave yard

sxr stock compression is 175-185. how much higher do you want it and for what purpose? ready to buy more than just pump gas? i've had 20 SXRs and let me tell you, they blow up and lose crank bearings soon enough without giving them reasons to blow up that much quicker.

- Location

- Ontario, Canada

i havent seen an sxr that has 175psi stock, i shaved mine 35 thou and it now has 175psi. from what i've seen the stock compression is like 160-168psi.... the manual does say that the compression is up around 175-185 but dont think many to little are.

Thats just what ive seen

Thats just what ive seen

- Location

- the jetski grave yard

your motor was either tired or at elevation. .035 is a huge cut. did you re chamber the domes or check squish? i think you said you only gained 10 psi? -.035 = 10lbs aint right.

- Location

- Cleveland Ohio

My SXR is at 157 both cylinders, always has been. (I have used several guages). My last SXR cylinder was at 162psi, stock.

Bump it up to 175, if it isn't at 175 now.

Bump it up to 175, if it isn't at 175 now.

- Location

- Ontario, Canada

your motor was either tired or at elevation. .035 is a huge cut. did you re chamber the domes or check squish? i think you said you only gained 10 psi? -.035 = 10lbs aint right.

Atmospheric pressure is 14.6 here in Ontario, 35 thousands is a decent amount but it gained more like 13psi and that was with a battery with 12.1V shouldnt really do it with less than 12.2V but im going to test again with 12.6V and i may get a little more on the gauge.

Never the less i took it for a rip and it is really noticeable in the low end to mid range, maybe 13psi gain for 35 thou off the head is low but im satisfied

- Location

- St Charles IL

elevation plays a part "kawi mods"

but i have three sxr motors. When each was stock untouched they were #1)150 #2)150 #3)165

I milled my heads to add 15 psi each so now im at #1)165 #2)165 #3)180

but i have three sxr motors. When each was stock untouched they were #1)150 #2)150 #3)165

I milled my heads to add 15 psi each so now im at #1)165 #2)165 #3)180

- Location

- Ontario, Canada

how much you mill?

- Location

- St Charles IL

- Location

- Sweet Valley, pa

My SX-R was 155 psi stock at 1200 feet, first mod I did was shave 0.020" and it put it at 175ish PSI. A few years down the road I did a mild port job and it bumped up to 183...I've got 6 years on the crank and have run nothing but pump gas with awesome results...

- Location

- Sweet Valley, pa

Recommend anyone on here to do the machine work?

I did my own, but any descent engine builder should be able to handle the task. I may still have my stock milled head if you are interested...

- Location

- Ontario, Canada

any machine shop will do it also i keep hearing that #zero does good work as well

- Location

- South OC, CA

I use Chris Newmiller of Newmiller Machine. His work is impeccable and his customer service is second to none.

nmachine@earthlink.net

nmachine@earthlink.net

- Location

- St Charles IL

you can have it recut but it may just be more beneficial to buy another one.Starting this one back up! Well since my sxr is down for the moment anyone mill the head and run temp sensor jump?? Would running 93 be good enough?? I want to clean this up a bit before reassembly.

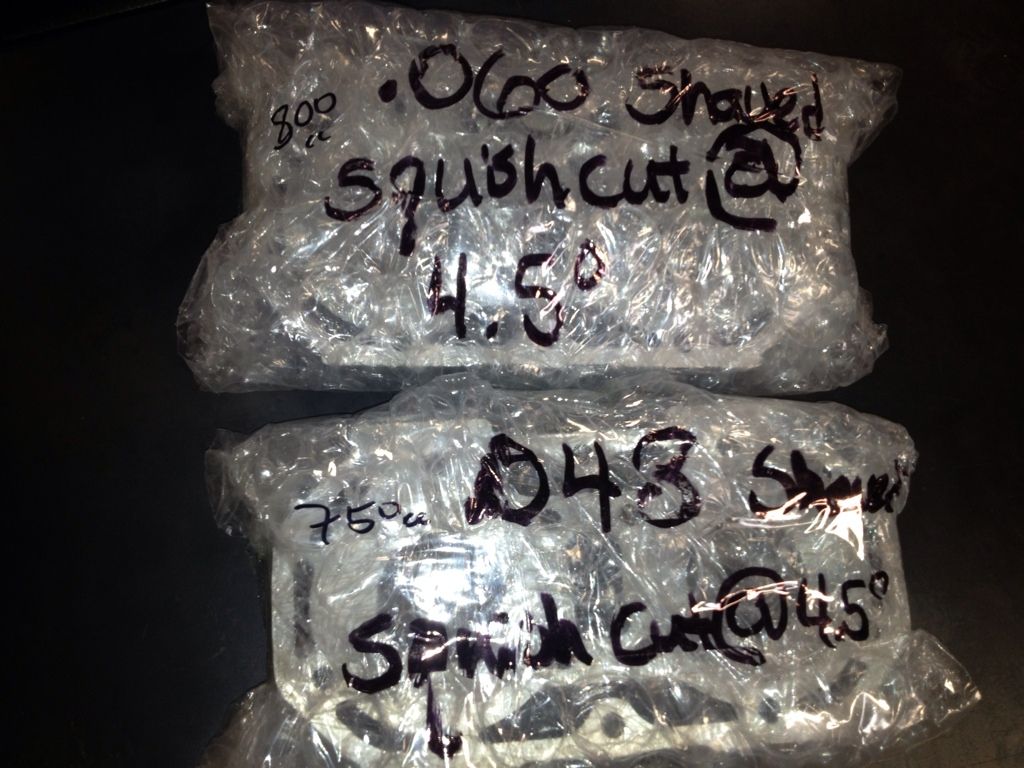

View attachment 221683

I run milled head, temp jump, n 93 octane

my motor had 150 psi n had it milled to 165 psi....my other sxr motor is 165 n i had it raised to 185

- Location

- Cleveland Ohio

Starting this one back up! Well since my sxr is down for the moment anyone mill the head and run temp sensor jump?? Would running 93 be good enough?? I want to clean this up a bit before reassembly.

View attachment 221683

While your at it, send your flywheel in too. Get that heavy kawi pig flywheel lightened up...it'll rip out of the hole. #zero I have heard does flywheels also.

- Location

- Australia/Florida/Oregon

I have bought 2 off Zero,s flywheel for my sxr1100 and sxr 800 love the mans work ! 1 off the best things in my mind is worth doing ! Buy a after market head mate , bin that one !While your at it, send your flywheel in too. Get that heavy kawi pig flywheel lightened up...it'll rip out of the hole. #zero I have heard does flywheels also.

Ok nice! are you running the temp jump with the 165 psi motor or both?you can have it recut but it may just be more beneficial to buy another one.

I run milled head, temp jump, n 93 octane

my motor had 150 psi n had it milled to 165 psi....my other sxr motor is 165 n i had it raised to 185