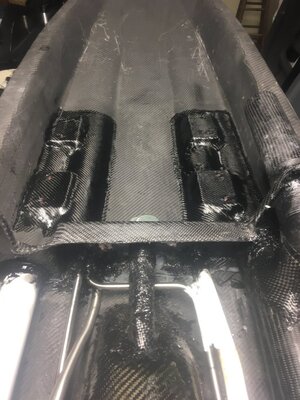

I have a Twangled Backie Chan, it has some very sketchy motor mounts, one has torn out completely and some of the others are a little wobbly.

I want to go through and redo all of them.

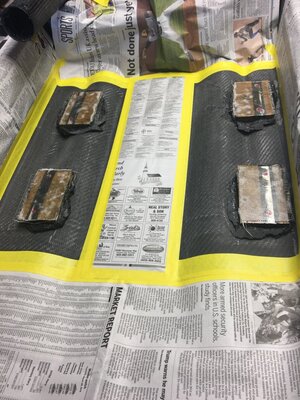

I can fairly easily make myself some nice peices of aluminum, but the bottom of the hull has a lot of shape to it, and the pieces of aluminum will be basically flat...so some sort of filler or spacer is going to be needed between the aluminum and the actual hull.

What do people use?

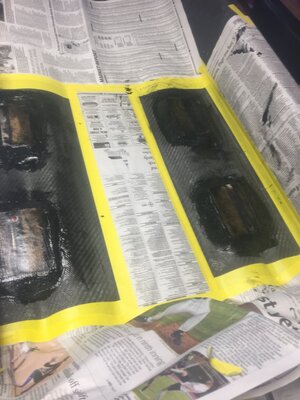

Also I'm interested in any info about what's appropriate for what sort of material and how thick and how many layers and whatnot for glassing them in.

I've searched around looking for any examples of people glassing in motor mount inserts but haven't found any.

Any help much appreciated.

I want to go through and redo all of them.

I can fairly easily make myself some nice peices of aluminum, but the bottom of the hull has a lot of shape to it, and the pieces of aluminum will be basically flat...so some sort of filler or spacer is going to be needed between the aluminum and the actual hull.

What do people use?

Also I'm interested in any info about what's appropriate for what sort of material and how thick and how many layers and whatnot for glassing them in.

I've searched around looking for any examples of people glassing in motor mount inserts but haven't found any.

Any help much appreciated.