- Location

- Cumming GA

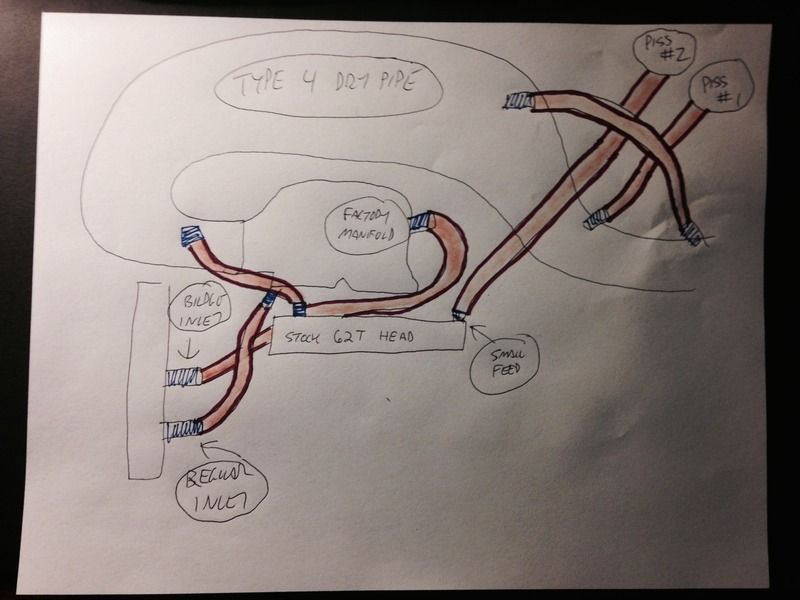

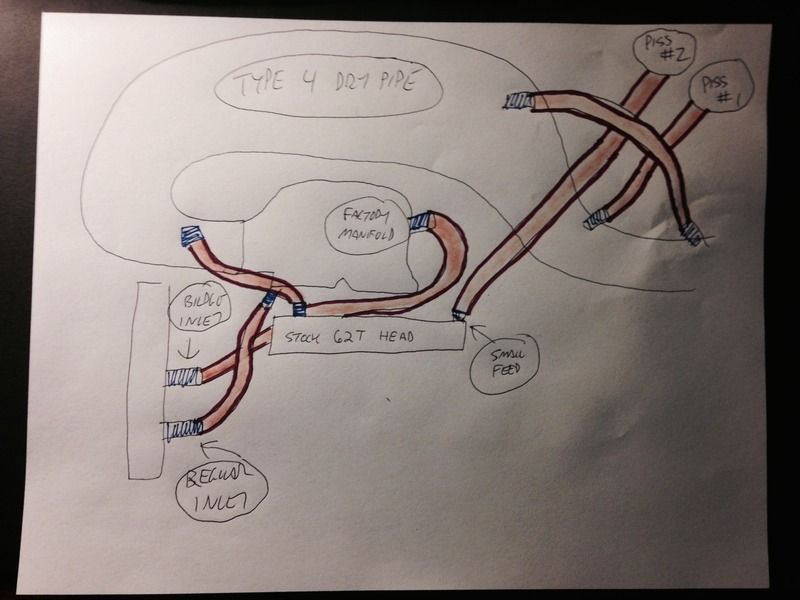

Ok I know I am pretty damned cool but I keep blowing Couplers on my Type 4 Dry Pipe.... I dont have dual cooling now but am going to tap into my Pump this weekend and ponied up for a new Coupler and a Bildge with switch... Before I go drilling in the Pump I would love to have a couple things confirmed... My Ski is bored .5 over and I capped the little fitting on the front of the Stock Head when I put the Dry pipe on. If I keep the stock head and run a second cooling line from my Bildge inlet to my Factory Manifold ( Which already has a second capped inlet on it) Do I just run the second pisser from that spot on the STOCK head? See my Diagram... I know Im no Picaso but I have the below planned to route just want to confirm all will be good...

Regular Inlet to Bottom of Mani

Bildge to Top of Mani

Head to Lower Pipe

Small fitting on Head to second Pisser

Any help would be appreciatted.... Thanks All!!!

Regular Inlet to Bottom of Mani

Bildge to Top of Mani

Head to Lower Pipe

Small fitting on Head to second Pisser

Any help would be appreciatted.... Thanks All!!!

Last edited: