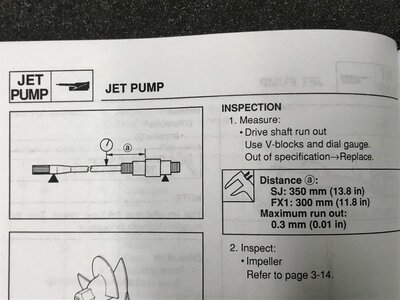

Yes your shaft tip is bent...

Both my shafts have that issue and have run fine as is... seems holding the shaft by tip with the spline tool and tightening and loosing prop during prop changes or the build bend/stresses the spline tip even more, they come with run out already new. One of mine got worse after a prop change..

What I do is try to split the difference.. bring half the amount that’s out of align to the other side..

On another note, I tried installing that tool to aligned pump then tighten pump But that didn’t work.. also I aligned pump with ski upside down only to find it went out of alignment when I flipped the ski over, ??? That was odd a F.. so had to readjust again..

I’d flip the ski over and align pump best you can while upright and split the run out in half by moving part of it to the other side..

So you’d eye ball it with the cold fusion tool, that lack of gap at 12 o’clock, we want to move 1/2 of that to 6 o’clock.

With ski upright, While re-aligning pump, read the lack of gap all the way around the hole between fixture and the guide that you slide... try to make the amount the same all the way around... also check by feel, the amount you have to push the shaft sideways to get the slide in the fixture, make that the same amount all the way around...