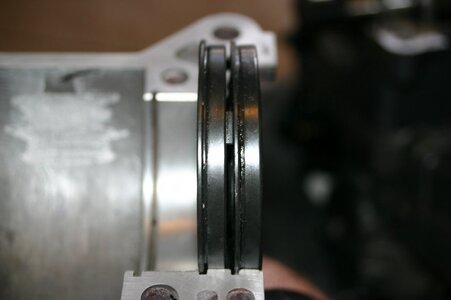

I just rebuilt this motor and have about 5 hours on it. It ran excellent till my last run at the lake a few days ago and it just died and wouldn't re-fire. I thought it was because I was almost out of fuel and I switched to reserve and had air in the fuel lines. Then after messing with it at home it just wasn't sucking fuel from the tank. I thought it was the fuel pump. Then today in the process of removing the fuel pump I just had a weird feeling about the seals and thought I should check on them. I took a flashlight and looked down between the case and the PTO cover and sure enough the rear seal is half way pushed out on one side which explains the lack of pulse to the fuel pump. My heart sunk!

I think I know what caused this. I bought a flush kit/hose to run it in the driveway and did this before my last trip to the lake. Unlike my outboard boat motor you are not supposed to turn the water on until you start the motor, well I did the opposite out of habit and I believe water entered the motor from the exhaust. I could hear the motor kind of hydraulic locking and pinging when it fired. After a few seconds that stopped and it ran fine. Do you guys think this is what pushed that seal out?

All that said - Can I tap that seal back in with maybe some sealant on it or am I doomed to having to having to tear the whole motor down again? I realize the seals have ridges on them which seat in the case haves but I don't know if people pop new seals in these things from the outside when necessary or what?

I am extremely upset about this - Please help ASAP. Thanks!

I think I know what caused this. I bought a flush kit/hose to run it in the driveway and did this before my last trip to the lake. Unlike my outboard boat motor you are not supposed to turn the water on until you start the motor, well I did the opposite out of habit and I believe water entered the motor from the exhaust. I could hear the motor kind of hydraulic locking and pinging when it fired. After a few seconds that stopped and it ran fine. Do you guys think this is what pushed that seal out?

All that said - Can I tap that seal back in with maybe some sealant on it or am I doomed to having to having to tear the whole motor down again? I realize the seals have ridges on them which seat in the case haves but I don't know if people pop new seals in these things from the outside when necessary or what?

I am extremely upset about this - Please help ASAP. Thanks!