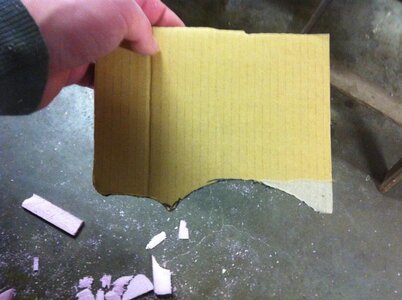

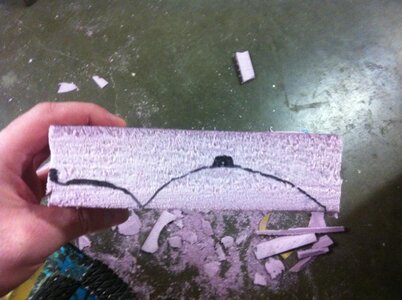

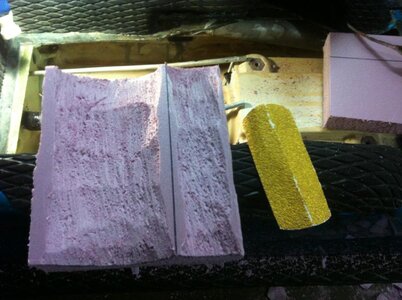

After a previose repair fialed I decided to cut an acces hole in the tray to get to the back side of the hole in the bottom deck After cuttting the hole I found a bunch of smelly water. At this point I knew this was going to be a complete defoam and I figured id better reinforced both chimes on either side of the pump tunnel and reinforce the rear bond rail as it was cracked. I used a few layers of 1710 biaxl and Evercoat SMC/Fiberglass resin.

Attachments

Last edited: