- Location

- Fargo, ND

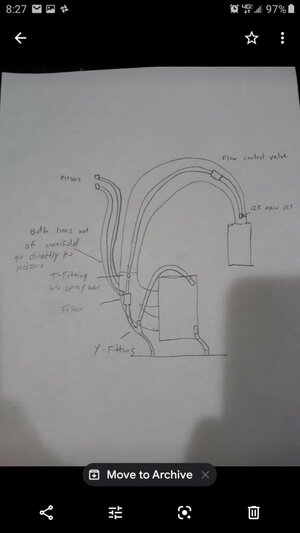

Anybody have a diagram of how to route my water lines for a Dry vs Wet setup on a power factor exhaust system?

Or a link to someone who has asked this question already...

Or a link to someone who has asked this question already...