You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

re sleeving

- Thread starter wetjet701

- Start date

wetjet701

Always On

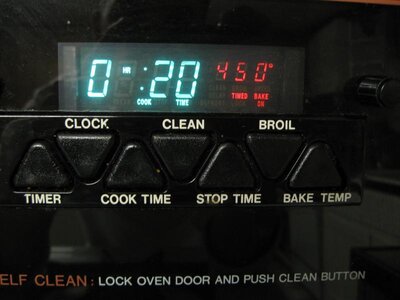

Once the oven hits 450 put the cylinder in the oven for 20min. After 20min remove set on a flat surface and smack the bottom of the sleeve with the mallet they should slide right out. If they don't, don't worry just put it back in the oven remember with this project heat is your friend.

Attachments

Last edited:

wetjet701

Always On

Once the sleeves are out put the cylinder back in the oven for 20min again. Remove put it in a vise get the sleeve from the freezer. Align the ports the sleeve will either drop in or just put the piece of woog on top of the sleeve and tap it a couple of times it should dop in smoothly. Remember do 1 sleeve at a time and bake cylinder 20min for each sleeve replacement. I only did one sleeve in this rightup.

Attachments

Freakrider

X247

- Location

- Tampa Bay area

any tips/tricks to align port before you tap it in ? if after you tap it in... it looks like 1mm off at the ports ...can a quick adjustment be made ?

WFO Speedracer

A lifetime ban is like a lifetime warranty !

- Location

- Alabama

You have like 30 sec or so to make any adjustments after that you have to reheat for 20 min then readjust.

Good write up... Wish the kawi cylinders were so easy.

You will most likely have a few seconds to move the sleeve around and line up the ports. You don't have a real long time so that's why you'd want to line them up fairly well before dropping it down.

You will most likely have a few seconds to move the sleeve around and line up the ports. You don't have a real long time so that's why you'd want to line them up fairly well before dropping it down.

- Location

- Louisville, Ky

i thought they had to be perfectly aligned? and only machine shops could do this? guess i'm mis-informed...

WFO Speedracer

A lifetime ban is like a lifetime warranty !

- Location

- Alabama

i thought they had to be perfectly aligned? and only machine shops could do this? guess i'm mis-informed...

Thats what they want you to think,keep thinking that way ,your pocket book will be much lighter that way.

wetjet701

Always On

any tips/tricks to align port before you tap it in ? if after you tap it in... it looks like 1mm off at the ports ...can a quick adjustment be made ?

It must be the picture because that sleeve is aligned properly

wsuwrhr

Purveyor of the Biggest Brapp

- Location

- Alta Loma, working in Upland

...a few things to add.

First,

Heat CAN BE your friend, but just don't get the cylinder too hot. 450 is pretty warm. You can easily anneal the cylinder by getting it too hot and letting it cool too slow.

Second,

The sleeve will need to be "seated" after it cools. It is no secret that when the cylinder is hot, it slightly expands or "grows" in size. The sleeve is cold, or better yet at room temperature. Well when the sleeve is dropped in, it rapidly heats up to the cylinder temperature, hense it grows as well. Well now as the parts cool, they shrink. The sleeve will not be sitting exactly on the counterbore step anymore.

Well this is all well and good until the cylinder head gets bolted down adding tons of pressure to the sleeves, or the motor detonates a few times, or the jetting gets a little lean and the motor gets nice and toasty.

Then the sleeves drop just slightly to sit on the c-bore step. Blown head gasket or o-ring.

Third,

I can't imagine the sleeve sitting exactly at the level of the cylinder deck, so it will be slightly sticking up or down in the hole, so it will need to be decked and bored anyway.

Brian

First,

Heat CAN BE your friend, but just don't get the cylinder too hot. 450 is pretty warm. You can easily anneal the cylinder by getting it too hot and letting it cool too slow.

Second,

The sleeve will need to be "seated" after it cools. It is no secret that when the cylinder is hot, it slightly expands or "grows" in size. The sleeve is cold, or better yet at room temperature. Well when the sleeve is dropped in, it rapidly heats up to the cylinder temperature, hense it grows as well. Well now as the parts cool, they shrink. The sleeve will not be sitting exactly on the counterbore step anymore.

Well this is all well and good until the cylinder head gets bolted down adding tons of pressure to the sleeves, or the motor detonates a few times, or the jetting gets a little lean and the motor gets nice and toasty.

Then the sleeves drop just slightly to sit on the c-bore step. Blown head gasket or o-ring.

Third,

I can't imagine the sleeve sitting exactly at the level of the cylinder deck, so it will be slightly sticking up or down in the hole, so it will need to be decked and bored anyway.

Brian

Kennay

Squarenose for the _____

- Location

- Myrtle Beach, SC

...a few things to add.

First,

Heat CAN BE your friend, but just don't get the cylinder too hot. 450 is pretty warm. You can easily anneal the cylinder by getting it too hot and letting it cool too slow.

Second,

The sleeve will need to be "seated" after it cools. It is no secret that when the cylinder is hot, it slightly expands or "grows" in size. The sleeve is cold, or better yet at room temperature. Well when the sleeve is dropped in, it rapidly heats up to the cylinder temperature, hense it grows as well. Well now as the parts cool, they shrink. The sleeve will not be sitting exactly on the counterbore step anymore.

Well this is all well and good until the cylinder head gets bolted down adding tons of pressure to the sleeves, or the motor detonates a few times, or the jetting gets a little lean and the motor gets nice and toasty.

Then the sleeves drop just slightly to sit on the c-bore step. Blown head gasket or o-ring.

Third,

I can't imagine the sleeve sitting exactly at the level of the cylinder deck, so it will be slightly sticking up or down in the hole, so it will need to be decked and bored anyway.

Brian

So after you get the sleeves in, bolt it to a stock head and stick em in the oven, remove and retighten. Complicated, eh.

Last edited:

wsuwrhr

Purveyor of the Biggest Brapp

- Location

- Alta Loma, working in Upland

Sarcasm, eh?

Suit yourself. I just thought a couple important steps were left out.

Suit yourself. I just thought a couple important steps were left out.

So after you get the sleeves in, bolt it to the top case and stick em in the over, remove and retighten. Complicated, eh.

Kennay

Squarenose for the _____

- Location

- Myrtle Beach, SC

Damn, I didn't mean to say the top case, I meant to say to a stock head

wsuwrhr

Purveyor of the Biggest Brapp

- Location

- Alta Loma, working in Upland

I am talking .005-.01 thousands, .1-.2 MM, not much gap, but IMHO, the sleeves need to be seated in a press.

Not veiwable in a picture, at least not by me.

Otherwise, good thread.

Brian

Not veiwable in a picture, at least not by me.

Otherwise, good thread.

Brian

Mine always drop directly in the counter bore that is why I use the wood block and mallet. Can't you tell in the last picture how well it is seated?

Last edited:

wsuwrhr

Purveyor of the Biggest Brapp

- Location

- Alta Loma, working in Upland

humility

Damn, I didn't mean to say the top case, I meant to say to a stock head

Kennay

Squarenose for the _____

- Location

- Myrtle Beach, SC

Who is humiliated? Nobody corrected me, and you didn't even catch the mistake. I did once I read it again.