I don't think I'm totally following what you're saying but adjusting a screw is so much easier than changing a jet. Plus you still have the problem of drilling out the screw which is exactly where the original poster is.

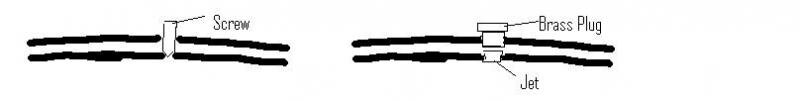

The attached pic might help a little better. I agree with adjusting but I'd suspect high % of people here are running off someone elses recommendations on turns and happy as can be. I know I am.

So say hypothetically it was known that a 110 jet equaled 1 turn and every half size was a 1/4 turn then it would be a one and done process. The drilling would be easier because it doesn't have to be precise. Ask anyone that's screwed with doing so or even going the oversize route it's a bitch.

I'm not saying I would prefer this over non-stuck screws but for anyone that has some jacked screws it could always be a save for the headpipe.

LMAO I agree it's the B-pipe way of life. What's more confusing to me is who honestley adjust's them or ever screw's with them again after they are dialed in?

Pro-Tec figured this out long ago JMO :smokin:

What's Pro-Tec do as I'm not familiar with their pipe.