Nik_Pilot

german guy

- Location

- Essen, Germany

Trying to get the B-Pipe tuned right!

I am not able to really dry out my pipe and so it produces not the power it should.

We all think that there is also too much water in the ATP waterbox...

I want to have bottom end power to midrange power for freestyle ride.

So my Setup consists of this:

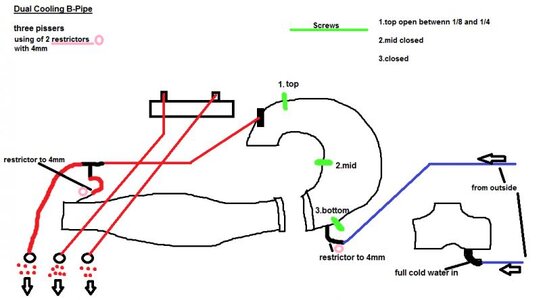

-Factory Mod B-Pipe

-ATP Waterbox

-Dual cooling lines

-3 pissers

-2 restrictors to 4mm

Here is a Photo from my actual setting(only the screws are not actual in the pic):

Now my idea is:

For the screws

-topscrew open to 1/8 - 1/4

-midscrew closed

-bottomscrew closed

smaller restrictor to stinger pipe with 2.5mm

Would be good if somebody could help me!

Thank you for your support!

I am not able to really dry out my pipe and so it produces not the power it should.

We all think that there is also too much water in the ATP waterbox...

I want to have bottom end power to midrange power for freestyle ride.

So my Setup consists of this:

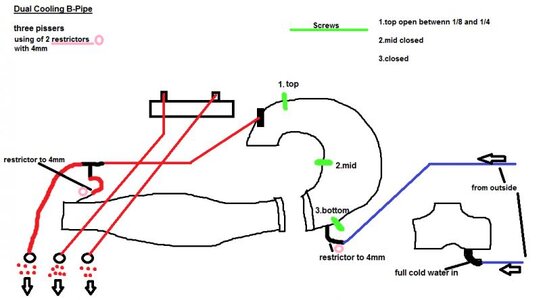

-Factory Mod B-Pipe

-ATP Waterbox

-Dual cooling lines

-3 pissers

-2 restrictors to 4mm

Here is a Photo from my actual setting(only the screws are not actual in the pic):

Now my idea is:

For the screws

-topscrew open to 1/8 - 1/4

-midscrew closed

-bottomscrew closed

smaller restrictor to stinger pipe with 2.5mm

Would be good if somebody could help me!

Thank you for your support!