This has been constantly evolving since moving down to Florida last year.

Started off as a clean, mostly stock 98 with an R&D pipe and some simple parts.

I stuck the hodge podge 760 that was in it so I built and ported a fresh 61x 760 and put in a B pipe. It has just been slowly progressing bit by bit from there.

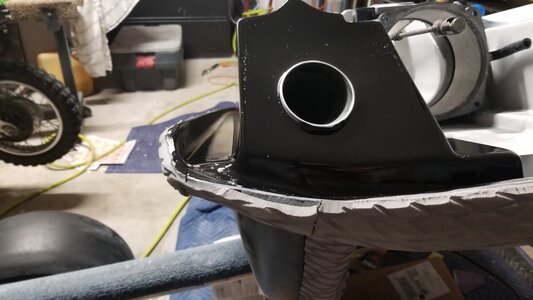

Has a Wamilton glass hood

KP pole with WDK steering

CarterB bolt on sponsons

Home ported 760 with zeeltronic

The usual other stuff.

Started off as a clean, mostly stock 98 with an R&D pipe and some simple parts.

I stuck the hodge podge 760 that was in it so I built and ported a fresh 61x 760 and put in a B pipe. It has just been slowly progressing bit by bit from there.

Has a Wamilton glass hood

KP pole with WDK steering

CarterB bolt on sponsons

Home ported 760 with zeeltronic

The usual other stuff.

Last edited: