Christian_83

Xscream

- Location

- Denmark

So im building a DASA 1100cc 10mm stroker for myself. The engien i bought of a friend, with a cracked sleeve.

I have rebuild engines before (bolt on and off). But never changed a sleeve. So i thought, this is the time to do it.

One important thing to say, when taking sleeves out and especially when putting them in - prep your work spae, the cylinder will be hot as a MF and you need to have everything in place to to the intented job, pretty quick.

So one think that tricked me was, i thought the dasa sleeves came CNC ported to match the cylinder. THe stroker sleeves are generic, so they fit 8mm, 10mm and 12mm.

So you have to port match them to your cylinder.

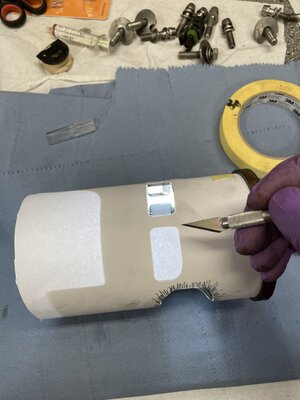

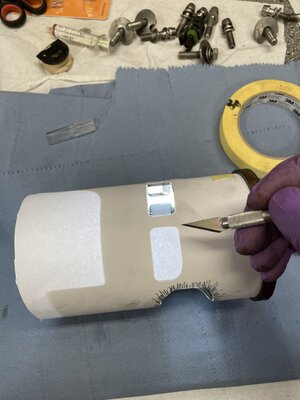

So first thing was cutting the old crack sleeve free to not lock, when getting it out.

next thing, heat cylinder up, to expan the aluminum to let the steel sleeves drop out. I used a weber grill, i would reccomend an oven to to this and have a but more controlled enviorment for heat.

I used an air saw to cut the bad part out, love this air saw. really nice.

I put the cylinder in the grill to try and get 150deg C

After this the sleeves popped out. pretty easy.

Next thing is to rougly portmap the old sleeves and transfer to new sleeves and port the rough part of new sleeves, before they are put in the cylinder.

Pay attention to the "deck height" is diffrent, some excess materiel is on new sleeves. so messaure from the undersige of the sleeeve, where it sits in the cylinder. I believe i messaure the new sleeve to be 1.92mm higher.

I also took a small bit of the cylinder, where it had some "bumps".

Next thing was to put sleeve back in, this is a bit more demanding, you have a narrow window to align the ports and get both sleeves to align correctly.

So prep everything and keep stuff close. I used a grill again, but next time i will use an oven.

The sleeves was garage temp, around 16deg C (not put in freezer) I will guess i have 30-40 seconds to adjust the sleeves, they heat up super fast

After i fitted the sleeves i put cylinder in the press with 2-3 tones until it was cooled down.

next thing i port matched the exhaust ports.

So for now, i need to wait to get my 90deg porting tool to finish poting transfers and then get cylinders bored and decked and then assembly the whole engine

I have rebuild engines before (bolt on and off). But never changed a sleeve. So i thought, this is the time to do it.

One important thing to say, when taking sleeves out and especially when putting them in - prep your work spae, the cylinder will be hot as a MF and you need to have everything in place to to the intented job, pretty quick.

So one think that tricked me was, i thought the dasa sleeves came CNC ported to match the cylinder. THe stroker sleeves are generic, so they fit 8mm, 10mm and 12mm.

So you have to port match them to your cylinder.

So first thing was cutting the old crack sleeve free to not lock, when getting it out.

next thing, heat cylinder up, to expan the aluminum to let the steel sleeves drop out. I used a weber grill, i would reccomend an oven to to this and have a but more controlled enviorment for heat.

I used an air saw to cut the bad part out, love this air saw. really nice.

I put the cylinder in the grill to try and get 150deg C

After this the sleeves popped out. pretty easy.

Next thing is to rougly portmap the old sleeves and transfer to new sleeves and port the rough part of new sleeves, before they are put in the cylinder.

Pay attention to the "deck height" is diffrent, some excess materiel is on new sleeves. so messaure from the undersige of the sleeeve, where it sits in the cylinder. I believe i messaure the new sleeve to be 1.92mm higher.

I also took a small bit of the cylinder, where it had some "bumps".

Next thing was to put sleeve back in, this is a bit more demanding, you have a narrow window to align the ports and get both sleeves to align correctly.

So prep everything and keep stuff close. I used a grill again, but next time i will use an oven.

The sleeves was garage temp, around 16deg C (not put in freezer) I will guess i have 30-40 seconds to adjust the sleeves, they heat up super fast

After i fitted the sleeves i put cylinder in the press with 2-3 tones until it was cooled down.

next thing i port matched the exhaust ports.

So for now, i need to wait to get my 90deg porting tool to finish poting transfers and then get cylinders bored and decked and then assembly the whole engine