Schmidty721

someone turf my rails

- Location

- WI

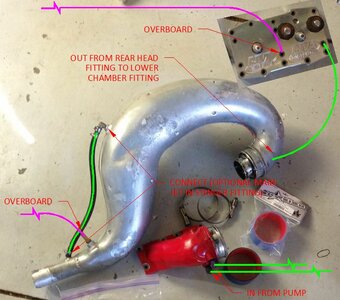

Anyone have experience with the water routing on a Speedwerx dry pipe. Photo of one installed in a ski or a diagram would be awesome.

Also, will going from a B-pipe to dry pipe require jetting changes or can I tune that with the High/Low needles?

780cc 5mil stroker, dual X-metal 46's, Total loss, and Speedwerx pipe.

Thanks for any help. Just trying to get some of this sorted before I stall assembling parts

Also, will going from a B-pipe to dry pipe require jetting changes or can I tune that with the High/Low needles?

780cc 5mil stroker, dual X-metal 46's, Total loss, and Speedwerx pipe.

Thanks for any help. Just trying to get some of this sorted before I stall assembling parts