Nightmare #1...

so I while ago get the jetlsport exhaust manifold and the connection between the two top studs to the cylinder case require two smaller studs (which I have)....I got one stud out of the case, but couldn't get the other out...so I grinded it down about a 1/2 ".

today I recieved the Kirker exhaust manifold and I like it better because the hole between going to the head pipe matches the 40 mm head pipe hole..where as the jetsport doesn't its 42 mm....but I realized that the stud i grinded isn't long enough for the kirker.....So once again I try to get the stud off..

Stupid me thought i could do it without buying bolt off...(drilling and reverse threading it.)...so I tried vise-grips wrenches and such...to no avail..

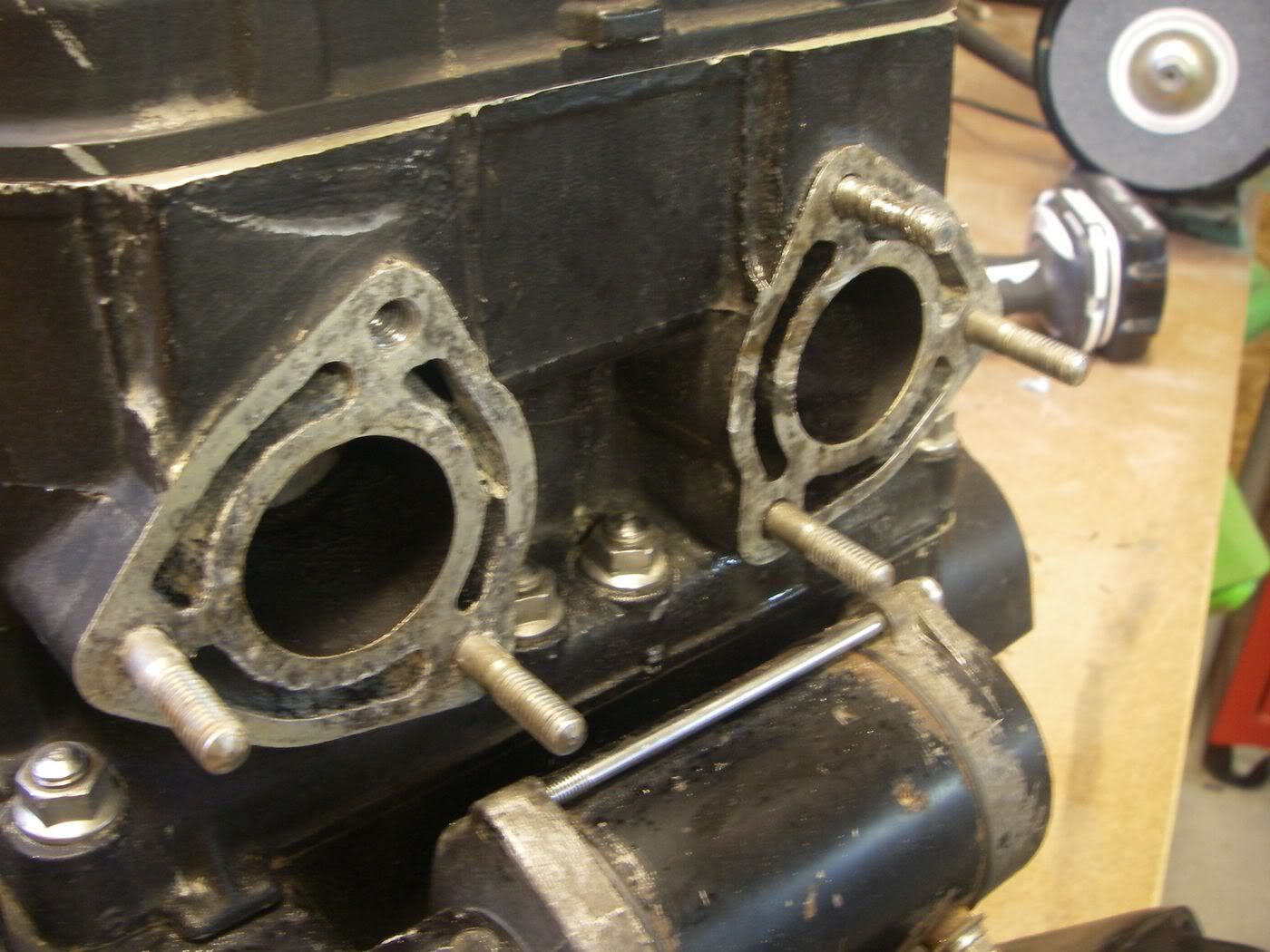

than i thought to put the whole damn motor on the bench vise...and i cranked it shut on that damn bolt with a four foot leverage pipe...proceeded to twist the motor...to no avail again! I took the motor off the bench vise.. and found a big old gash on the face of the exhaust port.

Now with that gash, I run the risk of an exhaust leak when running the engine.

aaahhhh!!! mother%^&*$#!! I'm so pissed.

is the cylinder case toast...or can i goup it up really good with high temp gasket sealer?

any advice greatly appreciated on this matter.