You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stock no more

- Thread starter aggro

- Start date

Great News! My cousin has a machine shop...and he welded a nut onto the remaining part of the stud. then in an interesting display he heated the nut and the surrounding area, proceeded to turn the nut, loosening in a back and forth manner...then he quickly grabbed this spray stuff (forgot what its called) that instantly cools to below freezing tempatures. and the stud twisted right out but snagged at the last part again. but he got it out Yeah!!!!

Whew as for the marring of the surface...he simply filed down the prudruding burrs and told me to just use the high temperature (red) gasket sealer.

Woohoo!! ust when all is lost!

anyway, so I put everything together snug as a bug!

I have a couple of questions though...

Upon putting the motor together..I realized that the 38 mm carb is a pull down throttle (not a pull up throttle).

Do I need to get another carb for my X2?

Or does anyone know how I can make it work?

Should I fabricate a 2inch wheel for the wire to wrap around and tap it onto the lever throttle?

Ideas Greatly appreciated

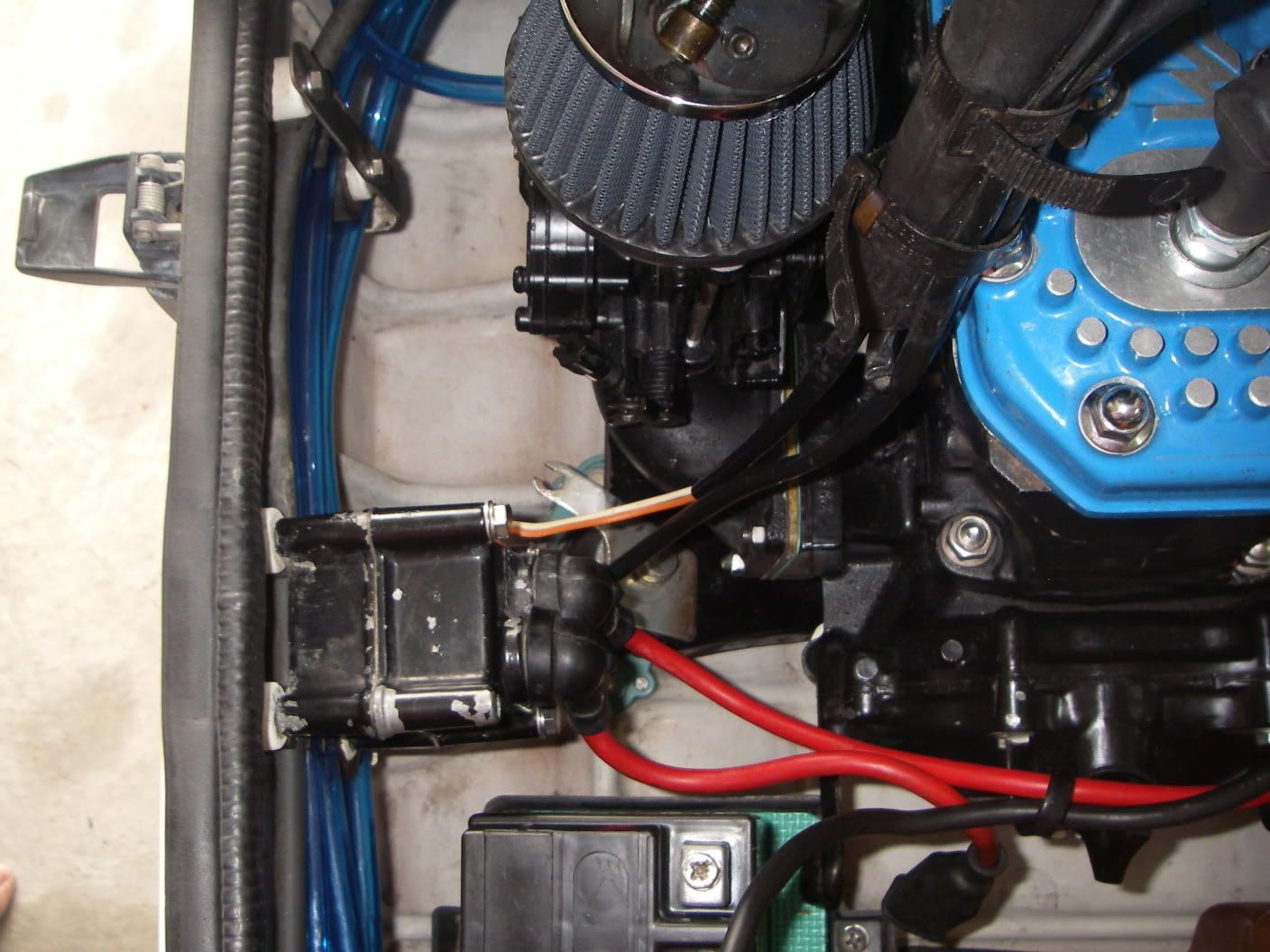

also (see second pic below)

My carb has few nipples that I'm unsure of what to do...

I know where the main and pilot lines (C and D) go, but I have know idea what to do with (E)... also there is a nipple coming ot of the case (A) that you can't see in the pic...is that where the pulse line goes?

and Im lost on smaller nipples (B and F)

can someone please help me?

Whew as for the marring of the surface...he simply filed down the prudruding burrs and told me to just use the high temperature (red) gasket sealer.

Woohoo!! ust when all is lost!

anyway, so I put everything together snug as a bug!

I have a couple of questions though...

Upon putting the motor together..I realized that the 38 mm carb is a pull down throttle (not a pull up throttle).

Do I need to get another carb for my X2?

Or does anyone know how I can make it work?

Should I fabricate a 2inch wheel for the wire to wrap around and tap it onto the lever throttle?

Ideas Greatly appreciated

also (see second pic below)

My carb has few nipples that I'm unsure of what to do...

I know where the main and pilot lines (C and D) go, but I have know idea what to do with (E)... also there is a nipple coming ot of the case (A) that you can't see in the pic...is that where the pulse line goes?

and Im lost on smaller nipples (B and F)

can someone please help me?

Last edited:

shawn_NJ

Chasing waves.

- Location

- Daytona Beach

You have to remove that external fuel pump shown hanging out the side in pic1. E connects to A on the cases. This is the pulse line that powers your 38's built in fuel pump. Then you just have the IN AND OUT on the carb (D&C). The R stamped on the carb (fitting C) indicates a RETURN to your fuel tank. B and F should be capped off. F I would fill with JBWELD then cap, you do NOT want any air leaks below the carb butterfly!!! My kawi motor X2s have a down pull. I run a 650sx throttle cable that allows the down pull. If you go hunting for a STOCK X2 38/40. They will have UP pull.

Last edited:

shawn_NJ

Chasing waves.

- Location

- Daytona Beach

Oh, I just noticed you have an 89 or 90! You NEED to reinforce that direct steer rod, or it WILL bend in half and snap! Your is already showing the signs of death coming soon!!!! TRUST ME, this just happened to my lightweight you have to do this before you go riding again. I made a killer aluminum tube with internal support for the steering rod. It protects it very well. It also helps to take the rubber caps off the steering rod and spray PB blaster and white lithium grease in it. Then reinstall.

Last edited:

dbrutherford

Parts Whore

- Location

- Fairmont, WV

Good to hear you got things sorted out. Next time just ask us and we will point you in the right direction. You better start buying your cousin lots of beer because he will be needed for custom parts fabrication!!!

Shawn is right, that steering rod is looking tweaked! Brace that bad boy up soon!

Shawn is right, that steering rod is looking tweaked! Brace that bad boy up soon!

Ok....Very cool! Thank You!! Shawn and DB!

A hunting I will go!

I have another question....about the exhaust cooling.

I have dual cooling set up on the exhaust manifold and the head then appropriately exiting...one of which through head pipe, then the stinger and a y out the hull pisser.......the other out the back bulkhead.

but I only have one source line (from the pump) going to a y and then into the exhaust manifold.

Is this OK? will it be enough water from the one source? or do I need to tap into the pump and run two lines from the pump for the dual cooling?

(if I do that, I'll just run a pisser out the side of the hull for the other exit instead of where it is now, going out the rear bulkhead)

But I'm worried is there enough substance to tap onto the other side of the pump? it looks pretty thin.

A hunting I will go!

I have another question....about the exhaust cooling.

I have dual cooling set up on the exhaust manifold and the head then appropriately exiting...one of which through head pipe, then the stinger and a y out the hull pisser.......the other out the back bulkhead.

but I only have one source line (from the pump) going to a y and then into the exhaust manifold.

Is this OK? will it be enough water from the one source? or do I need to tap into the pump and run two lines from the pump for the dual cooling?

(if I do that, I'll just run a pisser out the side of the hull for the other exit instead of where it is now, going out the rear bulkhead)

But I'm worried is there enough substance to tap onto the other side of the pump? it looks pretty thin.

Last edited:

shawn_NJ

Chasing waves.

- Location

- Daytona Beach

I had issues running single input cooling with two head fittings. My exhaust would get REALLY REALLY hot and motor very cool. I ended up taking both outlets off the head and putting them into a T, where both head fittings went into the headpipe. Then I had the stinger and pisser setup exactly as you do now. You can try to run it the way you have it, but keep an eye on the headpipe temp. Most people cap off the drain tube that goes to the bulkhead or they use it for a dual cooling line from the pump.

You have to remove that external fuel pump shown hanging out the side in pic1. E connects to A on the cases. This is the pulse line that powers your 38's built in fuel pump. Then you just have the IN AND OUT on the carb (D&C). The R stamped on the carb (fitting C) indicates a RETURN to your fuel tank. B and F should be capped off. F I would fill with JBWELD then cap, you do NOT want any air leaks below the carb butterfly!!! My kawi motor X2s have a down pull. I run a 650sx throttle cable that allows the down pull. If you go hunting for a STOCK X2 38/40. They will have UP pull.

about your pull down throttles you use....

Is it the 91-93 year 650sx throttle cable?

or the 87-90 year 650sx throttle cable?

also do you use a custom throttle bracket?

TIA

shawn_NJ

Chasing waves.

- Location

- Daytona Beach

The Westcoast and BCW intake manifolds (for use with mikuni 44/46 carbs) have a bracket for the throttle cable built in. I am using these on both of mine with 46mm SBN carbs. When I bought one of my X2's it has the stock 750SX carb & manifold installed on the 750 motor. That had a down pull and it had a bracket that mounts on the front motor mount with the bedplate. Its not hard to fab up your own bracket though. I have had to do that before. I didnt even know there were different 650sx cables. I just bought 3 off ebay a different times and never had an issue with one working.

Last edited:

WFO Speedracer

A lifetime ban is like a lifetime warranty !

- Location

- Alabama

What you have is single cooling split off to the maniflod,I agree with Shawn use the drain line going through the bulkhead as your second cooling line,you will need to pull the pump and drill and tap it for another fitting.Then take you second line coming from the head and connect it to a pisser out the side .That is true dual cooling two lines in,two lines out.

Yup I'm gonna do exactly that today...ThanksWhat you have is single cooling split off to the maniflod,I agree with Shawn use the drain line going through the bulkhead as your second cooling line,you will need to pull the pump and drill and tap it for another fitting.Then take you second line coming from the head and connect it to a pisser out the side .That is true dual cooling two lines in,two lines out.

The Westcoast and BCW intake manifolds (for use with mikuni 44/46 carbs) have a bracket for the throttle cable built in. I am using these on both of mine with 46mm SBN carbs. When I bought one of my X2's it has the stock 750SX carb & manifold installed on the 750 motor. That had a down pull and it had a bracket that mounts on the front motor mount with the bedplate. Its not hard to fab up your own bracket though. I have had to do that before. I didnt even know there were different 650sx cables. I just bought 3 off ebay a different times and never had an issue with one working.

ok I fabbed a bracket up...tested it...yeah it looks like its gonna work really good..it's the exact distance needed for the cable string.

Thanks for the heads up...now all I have to do is buy a SX Throttle Cable.

Jet ski haven has one for 30 bones. might get that and I'm set!

Thanks again Shawn!

madscientist

chilling with these guys.

- Location

- good old p'cola

the cooling system will flow a little better w/ some aftermarket pissers those stockers are 1/2 the size of the a/m ones

wadman

wadman

- Location

- winsted CT

lookin good

dbrutherford

Parts Whore

- Location

- Fairmont, WV

the cooling system will flow a little better w/ some aftermarket pissers those stockers are 1/2 the size of the a/m ones

X2 and use 3/8" lines to them instead of 1/4" lines.

- Location

- Amherst NH

Looking good. That thing is gonna move right out. Also you might think about putting an inline filter coming out of the gastank. $1 part at the auto store.

shawn_NJ

Chasing waves.

- Location

- Daytona Beach

You should grind the 1/8" water fitting flush with the pump....on the INSIDE of the pump. Mine didnt flow right until I did this. And DEF use AM pisser fittings.

You should grind the 1/8" water fitting flush with the pump....on the INSIDE of the pump. Mine didnt flow right until I did this. And DEF use AM pisser fittings.

I did grind it flush.. and Yeah I ordered the pissers.

I tell yah... the water was flowing very nice out of the rubber pissers..and the motor wasn't very hot to the touch...Impressive.

But I couldn't wait I went out today for a test run...and yeah it started right up, hooked right up and flew right out of there...I'm happy!

I didn't tune the carb not one bit...from when I recieved it in the mail....Lucky me!

Wooohoo!!! I wasn't use to the turning power...its got bottom and top end! definately noticable. gonna have to play with it a little more to get use to it....HAH!

There are a few things i still need to do ...like put a bilge pump in it, and a airfillter water cover..and also a primer kit...all of which are in the mail right now.

and I'm still gonna put a 750 in it for next season....but I'll ride this season out on this...it's fun enough for me!