WFO Speedracer

A lifetime ban is like a lifetime warranty !

- Location

- Alabama

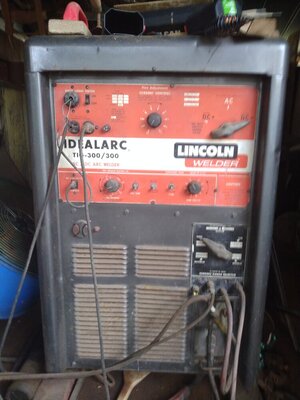

I feel you on the space issue, I inherited a barn so now instead of trying to get everything in one shop I have it broken up into sections, I have a section for parts storage , a loft to store motorcycles, several places to store project hulls etc, a welding section and a block garage to work on stuff in. it's worked out much better for me , I will make a suggestion though look into a multiprocess machine that can do pretty much anything instead of a bunch of separate welders.

One tip an old school welder taught me is always brake off the flux on the end of the rod when you finish welding , tap it on the cement floor or break it off with your hand. doesn't matter, it makes striking the arc next time much easier with the flux out of the way.

,

One tip an old school welder taught me is always brake off the flux on the end of the rod when you finish welding , tap it on the cement floor or break it off with your hand. doesn't matter, it makes striking the arc next time much easier with the flux out of the way.

,

Last edited: