You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Thread

- Thread starter Big Kahuna

- Start date

Jcary85

Site Supporter

- Location

- Glenmoore pa

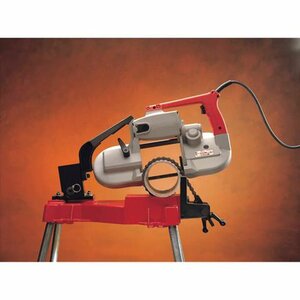

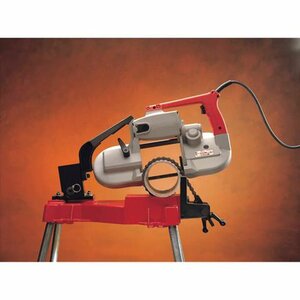

Love my portable band saw stand. One of the best tools I’ve ever made! Also love my two post lift. Really a life changer when you work on cars a lot.

Attachments

Their setup is nice. I just couldnt justify the money when I had the materials there. I bought the saw on sale at harbor freight for 99 bucks measured and drilled two holes and then ground/cut a slot in for the blade to pass thru. Less than a hour of work and I had it up and running. Next up is to make a horizontal attachment for the saw.

Their setup is nice. I just couldnt justify the money when I had the materials there. I bought the saw on sale at harbor freight for 99 bucks measured and drilled two holes and then ground/cut a slot in for the blade to pass thru. Less than a hour of work and I had it up and running. Next up is to make a horizontal attachment for the saw.

- Location

- Long Island ny

Who needs it to be bent? Cut the edges off and weld them on to make your 90Their setup is nice. I just couldnt justify the money when I had the materials there. I bought the saw on sale at harbor freight for 99 bucks measured and drilled two holes and then ground/cut a slot in for the blade to pass thru. Less than a hour of work and I had it up and running. Next up is to make a horizontal attachment for the saw.

OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

You guys are making me regret selling my Milwaukee Deep Cut portable bandsaw.

That vise mount was on my list for a long time but I had always planned to just build one. Ironically, I have the material and time now, but not the bandsaw anymore.

I also wanted the stand and pivot but they wanted as much for it as the saw itself.

That vise mount was on my list for a long time but I had always planned to just build one. Ironically, I have the material and time now, but not the bandsaw anymore.

I also wanted the stand and pivot but they wanted as much for it as the saw itself.

Contemplated it, my tig is down right now and bending it would give me a nice transition. I may cut down the backside with an angle grinder on the bend line, bend in vise and run a bead on bottom side to keep the top smooth.Who needs it to be bent? Cut the edges off and weld them on to make your 90

OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

Speaking of bending metal, I used my vise brake the other day to bend some 1/8” aluminum for my fuel jug rack. It worked, but was very close to the limit of my vise.

Does anyone have the 10” version for the hyd shop press?

Does anyone have the 10” version for the hyd shop press?

I have version of that 10" press brake that came from Northern Hydraulics 20 yrs ago, still going strong.Wow,l like that little 10” press! Who has them

OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

Amazon has quite a few to choose from but here's one for $229.

https://www.amazon.com/Eastwood-Att...9Y2xpY2tSZWRpcmVjdCZkb05vdExvZ0NsaWNrPXRydWU=

But, I did find this unit which I think meets all of my criteria for a bender . I doubt I am ever needing to bend more than 4" and it's small enough to store away in between uses.

https://www.amazon.com/KAKA-Operate...B883GNGA05Z43WJ36NX&psc=1&qid=1582114013&s=hi

https://www.amazon.com/Eastwood-Att...9Y2xpY2tSZWRpcmVjdCZkb05vdExvZ0NsaWNrPXRydWU=

But, I did find this unit which I think meets all of my criteria for a bender . I doubt I am ever needing to bend more than 4" and it's small enough to store away in between uses.

https://www.amazon.com/KAKA-Operate...B883GNGA05Z43WJ36NX&psc=1&qid=1582114013&s=hi

Jcary85

Site Supporter

- Location

- Glenmoore pa

I’ve contemplated buying one of these “builder” kits for the shop press brake setup. They have loads of options but the cheapest kit is like $180...

https://www.swagoffroad.com/SWAG-Press-Brake-Kits_c_53.html

https://www.swagoffroad.com/SWAG-Press-Brake-Kits_c_53.html

So thru a buddy and facebook (which I dont have) he met a guy over the weekend who builds offroad toyotas. We mentioned that I needed to bend some plate so I went by there tonight after work. He had the swag finger brake and a 20 ton harbor freight press. Took some muscle and some stacking of additional pieces of angle iron in there but he bent up my table saw plate just like I wanted. It definitely put some stress on the press was bending the top plate of the press upward pretty good.

Going to look at a small milling machine tomorrow. I have never owned a mill, much less used one, but have wanted one for a long time. Its about 400 lbs or so, trying to figure out how to get it from my truck onto the cart I had my lathe on. Guy says it includes tooling, any pointers on what to check for besides loose ways, spindle wobble etc?

smokeysevin

one man with a couch

- Location

- Houston

Do you have more specifics on the machine? Does it have an adjustable head? Is it a knee mill?Going to look at a small milling machine tomorrow. I have never owned a mill, much less used one, but have wanted one for a long time. Its about 400 lbs or so, trying to figure out how to get it from my truck onto the cart I had my lathe on. Guy says it includes tooling, any pointers on what to check for besides loose ways, spindle wobble etc?

Sean

Sent from my LM-G710 using Tapatalk

- Location

- Western NY

Funny I'm in the process of making one of these right now for a 20 ton pressSpeaking of bending metal, I used my vise brake the other day to bend some 1/8” aluminum for my fuel jug rack. It worked, but was very close to the limit of my vise.

Does anyone have the 10” version for the hyd shop press?

Going to look at a small milling machine tomorrow. I have never owned a mill, much less used one, but have wanted one for a long time. Its about 400 lbs or so, trying to figure out how to get it from my truck onto the cart I had my lathe on. Guy says it includes tooling, any pointers on what to check for besides loose ways, spindle wobble etc?

Best advise I can give, don't buy a 400lb mill lol, that's more like a light drill press. Last bridgeport clone I bought was $300, not sure what your looking at spending but you can get something with some capability for cheap.

- Location

- Western NY

jealous of your front porchWent from a 24’x40 workshop to this rental last August. Working on buying a lake house so hopefully we’ll close on one next week. First order of business is building a workshop that’s better then my last one.

View attachment 388597

How often do you guys with porta-band stands wish you had something with a wider throat? I'm starting to look at budget band saw options but am afraid I'll always be wishing I had something that can cut bigger pieces of plate. Otherwise who's got a larger metal bandsaw they recommend?

smokeysevin

one man with a couch

- Location

- Houston

How often do you guys with porta-band stands wish you had something with a wider throat? I'm starting to look at budget band saw options but am afraid I'll always be wishing I had something that can cut bigger pieces of plate. Otherwise who's got a larger metal bandsaw they recommend?

All the time, you really have to plan your cuts. Budget and space has kept me from upgrading.

Sean