- Location

- near beautiful bobcaygeon

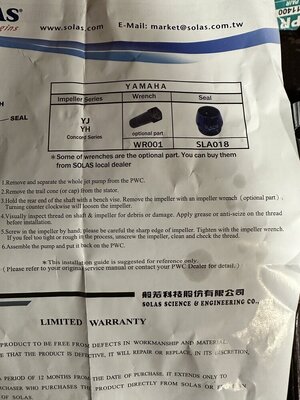

A few weeks back I swapped SJ4 stock impeller for a Solas Concord to go with a stage 1 type tune (using maptuner nano). I have been doing some other things with it as well and so today was first time I ran it to warm it up to do an oil / filter change. I noticed what seemed like a metal dinging sound that seemed to be coming from the pump area. I could hear it most when underneath and looking up at the impeller through the grate or listening and the nozzle. I could hear the sound even as starter was turning shaft before engine fully fired, so it definitely seem like it had to do with impeller turning in the pump. I have hearing aids and so not great with some sounds and cannot recall how much or if different than with stock impeller and can't really recall what exactly it used to sound like on the hose.

When i put the new impeller onto the pump it threaded on very smooth and even while threading down it was making no contact with the outer ring. Once in place I could turn it by hand and all seemed smooth an no sign or sound of part of impeller touching or rubbing. When i reinstalled the pump to the ski i am pretty sure the splines all lined up properly and everything went back together fitting properly.

In any case, I felt a bit uncomfortable with this sound and so pulled the pump off again, pulled the reduction nozzle off pump, and pulled the cone covering back end of pump off. When i spun the impeller by hand all felt smooth and no sign or feel or sound of anything rubbing. I pulled off the impeller and it looks totally clean - no signs anywhere that any part of it was making contact with anything.

I wish i had recorded the sound but too late now.

Does anybody have any thoughts or suggestions?

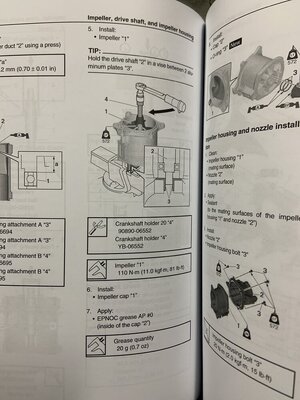

One thing I am wondering about regards the torque for reinstallation of the impeller. I have to say, when i first installed the impeller I did not tighten it down super hard and did not use a torque wrench. I am wondering now if this may not have been tight enough and that this left enough play to account for some movement and the sounds? Is this plausible?

What should the impeller be torqued down to?

I am about to put it back together but don't know the torque. I guess i should have bitten the bullet and paid for the service manual a long time ago. I might have to cough for one month e-book access to the manual.

When i put the new impeller onto the pump it threaded on very smooth and even while threading down it was making no contact with the outer ring. Once in place I could turn it by hand and all seemed smooth an no sign or sound of part of impeller touching or rubbing. When i reinstalled the pump to the ski i am pretty sure the splines all lined up properly and everything went back together fitting properly.

In any case, I felt a bit uncomfortable with this sound and so pulled the pump off again, pulled the reduction nozzle off pump, and pulled the cone covering back end of pump off. When i spun the impeller by hand all felt smooth and no sign or feel or sound of anything rubbing. I pulled off the impeller and it looks totally clean - no signs anywhere that any part of it was making contact with anything.

I wish i had recorded the sound but too late now.

Does anybody have any thoughts or suggestions?

One thing I am wondering about regards the torque for reinstallation of the impeller. I have to say, when i first installed the impeller I did not tighten it down super hard and did not use a torque wrench. I am wondering now if this may not have been tight enough and that this left enough play to account for some movement and the sounds? Is this plausible?

What should the impeller be torqued down to?

I am about to put it back together but don't know the torque. I guess i should have bitten the bullet and paid for the service manual a long time ago. I might have to cough for one month e-book access to the manual.