- Location

- SF Bay Area, CA

This was my first jet ski I owned ( own 3 now) when I got this baby it had a shattered piston bad crank seals and a blown crank. I put turf on it updated the motor a little at a time, and has been by far my most reliable ski. This has been a long time coming. to get a make over and update!

The plan:

- I'm converting it to a Reed with the Westcoast rc520 Cylinder

- 75.5 Wiseco Pistons

- Westcoast Dual 38 Intake Manifold

- Westcoast Velocity stacks x2

- Westcoast head( interchangeable domes ( going to use a cloth headgasket instead of metal)

- Westcoast Exhaust Manifold

- Westcoast Pipe (5 ring)

- Westcoast Bulkhead Brace

- Westcoast dual scoop hood

- Westcoast Waterbox

- Westcoast Bilge Relay

- Rule 500 GPH bilge

- Lightned Flywheel

- Welded Crank

- Westcoast OS Tank

- Westcoast Ride plate

- Westcoast Intake Grate

- 440 Pump with a 16.5 skat

- Converting from Nose exhaust to Rear.

- Westcoast Themed Paint

- Dual Cooling

- New turf (might do Jet Trim)

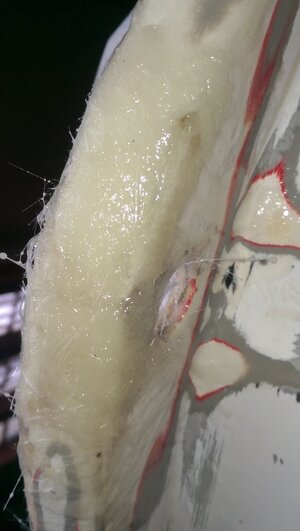

- Truing the hull as well as reparing

The plan:

- I'm converting it to a Reed with the Westcoast rc520 Cylinder

- 75.5 Wiseco Pistons

- Westcoast Dual 38 Intake Manifold

- Westcoast Velocity stacks x2

- Westcoast head( interchangeable domes ( going to use a cloth headgasket instead of metal)

- Westcoast Exhaust Manifold

- Westcoast Pipe (5 ring)

- Westcoast Bulkhead Brace

- Westcoast dual scoop hood

- Westcoast Waterbox

- Westcoast Bilge Relay

- Rule 500 GPH bilge

- Lightned Flywheel

- Welded Crank

- Westcoast OS Tank

- Westcoast Ride plate

- Westcoast Intake Grate

- 440 Pump with a 16.5 skat

- Converting from Nose exhaust to Rear.

- Westcoast Themed Paint

- Dual Cooling

- New turf (might do Jet Trim)

- Truing the hull as well as reparing

Last edited: