What are the basic parts of the WET JET pipe? The pipe comes in 3 pieces (plus harware, gaskets, crush washers, a bracket, etc). The 3 main pieces are the manifold, the head pipe, and the tail cone.

Can I bolt it straight into my SuperJet or Blaster? NO. I have no experience installing it in a Blaster, but I did put one in a SN Superjet. The tailcone has to be cut and rotated so that the exit points towards the stock water box.

What kind of pipe is it? I've seen it called a wet pipe and a dry pipe. More on that in a minute.

What about water routing? In the pictures it looks like it has 42 water fittings/holes.

Most of the holes are for the mounting bracket that secures the HEAVY pipe to the stock cylinder head. I cut and modified my bracket so it works with my Protec Recreational head.

Looking at individual parts -

1. The manifold is pretty simple, but due to an odd casting it doesn't use all the bolts. Seems to be leak free on my ski though. It is set up for single cooling. I'm not sure how easy it would be to add another cooling inlet line.

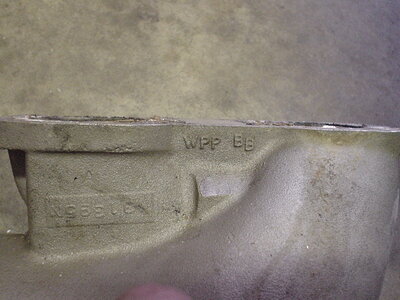

Here is a pic of the complete pipe and a close up of some text on the exhaust manifold.

Aaron