- Location

- Asheville, NC

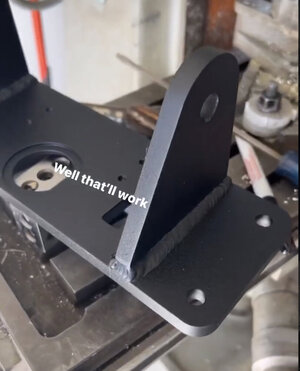

My handlepole bracket on the Krash was stripped badly on multiple holes for the mounting. I got a helicoil set for M8x1.25 and bought a new drill bit. I drilled the holes out nicely and to the correct depth, and started to tap the holes. I’ve used all kinds of taps and dies for 20 years and I’ve never had one do this. I oiled the tap and started it in the hole. It felt normal going in, but nearly locked solid when I started to back it out. It pulled the threads out that it had just cut… I tried another 2 holes before realizing the new tap in the helicoil set had a burr on the end of it that was just dragging all the way out. Anyways, I don’t feel like buying key lock inserts to fix this and would like someone that knows how to properly repair it. Can somebody tell me who can fill these holes and re-tap them? I ordered a new bracket through JS Powersports almost 2 months ago and there is no telling when it will show up or if it will fit property. Krash has a proprietary size handlepole bracket and SJ spacing does not fit.