- Location

- Fresno, CA

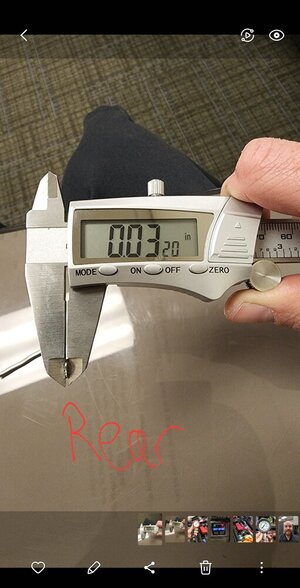

I recently finished breaking in my SBT Yamaha 61x/62T 701 and decided to put my ADA girdled head on with 35cc domes. After installing the head I did a compression test which read about 195 PSI in both holes. With the stock head, the PSI is about 175. I also tested compression with a Snap-On guage and an Autozone loaner and the results were about the same (190 to 195 PSI). This made me go an check squish with the ADA head installed and the readings were about 0.034 in both holes. I am limited on time as I plan to ride this weekend so I am tempted to just run it with 91 octane pump gas and see what happens but I want some more opinions first. Will is be relatively safe to run compression that high with pump gas? I ride freestyle and do mostly old school tricks like subs, fountains, and slides. I do like to go WOT on occasion but usually only for 10 seconds or less.

Full Specs:

Yamaha 61x/62T SBT (stock bore)

Limited B Pipe

TDR waterbox

Lightened Flywheel

MSD enhancer

Yamasaki coil

ADA girdled head with 35cc domes

Dual Mikuni SBN 38

VForce 2 Reeds

I am also considering putting the stock head (64u) back on until I can get custom cut domes to resolve the squish issue. Please let me know as I am torn on which way to go at this point. I want to just send it! lol

Full Specs:

Yamaha 61x/62T SBT (stock bore)

Limited B Pipe

TDR waterbox

Lightened Flywheel

MSD enhancer

Yamasaki coil

ADA girdled head with 35cc domes

Dual Mikuni SBN 38

VForce 2 Reeds

I am also considering putting the stock head (64u) back on until I can get custom cut domes to resolve the squish issue. Please let me know as I am torn on which way to go at this point. I want to just send it! lol