- Location

- New York Crew

Well as I'm sure most of you know my ski weighs 340 lbs, so its time to refoam. Here is my weight thread: http://www.x-h2o.com/threads/65272

And here's some stuff where I first started workin on it: http://www.x-h2o.com/threads/48684

Originally it was Newman's ski, that I helped him build and did the front reinforcing with him on it back in 06. It is still holding up fine so, now its time to do the same on the back, plus to make sure it does not get wet again.

So far I have over 20 hrs into the reinforcing foam job. It's taking longer than I expected, but oh well, its a few months till Daytona.

First I removed the turf I think I put it on way to good, it took forever to get off. Little scraps with a razor sharp putty knife. That took two nights after work. Then it was on to grinding off the old fiberglass and removing the Blowsioin Kicker footholds. Well again I think I put them on to good. That took a whole night and I had to drill out the pop reivets, graind off all the fiberglass, then break them out in 3 to 4 pcs each.

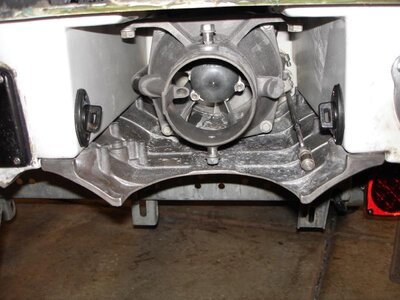

Next was pregrinding everything so I don't have to do it later. Then I cut the tray out, being careful not to cut thru to the pump area. Popped that out and started the tedious task of removing the wet foam. There is another two nights.

Finally I got it down where I could sand it with some 60 grit, and started putting 5 min epxoy on the bond line, pipe inlets/outlets, etc. Next it was time for the fiberglass reinforcing. I used US composites 12oz biax, with their 635 epoxy, 4:1. Luckily its been a great week here so I could work outside, hopefully it keeps up again this week.

Once the fiberglass set up, it was time to start fitting up the Dow Styrofoam. This only has about a 25lb/sq in rating compared to the 40-60 lb/sq in rating of the urethane foam, but it won't hold water. Hopefully the 12oz will be strong enough to make up the difference. I thought about adding ribs to the sides, but decided against it. I used about 8oz of resin per side.

And here's some stuff where I first started workin on it: http://www.x-h2o.com/threads/48684

Originally it was Newman's ski, that I helped him build and did the front reinforcing with him on it back in 06. It is still holding up fine so, now its time to do the same on the back, plus to make sure it does not get wet again.

So far I have over 20 hrs into the reinforcing foam job. It's taking longer than I expected, but oh well, its a few months till Daytona.

First I removed the turf I think I put it on way to good, it took forever to get off. Little scraps with a razor sharp putty knife. That took two nights after work. Then it was on to grinding off the old fiberglass and removing the Blowsioin Kicker footholds. Well again I think I put them on to good. That took a whole night and I had to drill out the pop reivets, graind off all the fiberglass, then break them out in 3 to 4 pcs each.

Next was pregrinding everything so I don't have to do it later. Then I cut the tray out, being careful not to cut thru to the pump area. Popped that out and started the tedious task of removing the wet foam. There is another two nights.

Finally I got it down where I could sand it with some 60 grit, and started putting 5 min epxoy on the bond line, pipe inlets/outlets, etc. Next it was time for the fiberglass reinforcing. I used US composites 12oz biax, with their 635 epoxy, 4:1. Luckily its been a great week here so I could work outside, hopefully it keeps up again this week.

Once the fiberglass set up, it was time to start fitting up the Dow Styrofoam. This only has about a 25lb/sq in rating compared to the 40-60 lb/sq in rating of the urethane foam, but it won't hold water. Hopefully the 12oz will be strong enough to make up the difference. I thought about adding ribs to the sides, but decided against it. I used about 8oz of resin per side.

Attachments

-

DSC03041-01.jpg72.8 KB · Views: 233

DSC03041-01.jpg72.8 KB · Views: 233 -

DSC03038-01.jpg56.4 KB · Views: 294

DSC03038-01.jpg56.4 KB · Views: 294 -

DSC03064-01.jpg40.6 KB · Views: 272

DSC03064-01.jpg40.6 KB · Views: 272 -

DSC03063-01.jpg26 KB · Views: 274

DSC03063-01.jpg26 KB · Views: 274 -

DSC03062-01.jpg50.9 KB · Views: 241

DSC03062-01.jpg50.9 KB · Views: 241 -

DSC03060-01.jpg54.6 KB · Views: 251

DSC03060-01.jpg54.6 KB · Views: 251 -

DSC03059-01.jpg72.1 KB · Views: 302

DSC03059-01.jpg72.1 KB · Views: 302 -

DSC03055-01.jpg59.2 KB · Views: 278

DSC03055-01.jpg59.2 KB · Views: 278 -

DSC03048-01.jpg55.4 KB · Views: 312

DSC03048-01.jpg55.4 KB · Views: 312 -

DSC03045-01.jpg49.9 KB · Views: 301

DSC03045-01.jpg49.9 KB · Views: 301

Last edited: