Im putting the big bore La sleeves in a 61x cylinder. Im going with 85mm Kawasaki flattop pistons. I know the kawi pistons are shorter than the yamahas by about 3.8mm. So if i mill the top of the cylinder to get my squish right arent i reducing my area for compression? So id need to run smaller cc domes to get compression higher? Seems like if you run the kawi pistons you have a less effective stroke?? more of the stroke is in the port area and not in compression area. Yes or no?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

big bore ??

- Thread starter RideItLikeYouStoleIt

- Start date

also the exhaust ports are about .1 inches higher than the stock 61x sleeve which is roughly 2.58mm. I was wondering if i could mill the cylinder deck first the required amount and then drop the sleeves in? I wasnt sure if this was ok or if id run into problems. How did everyone else do it?

bad93blaster

X-H2

are you getting r&d pistons?

Nope. already have kawi 85mil flat tops that ill cut the skirts on.

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

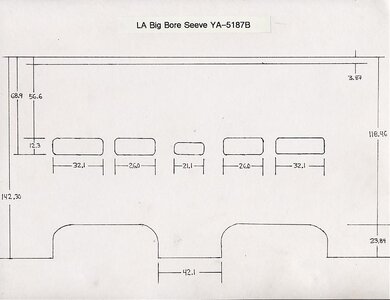

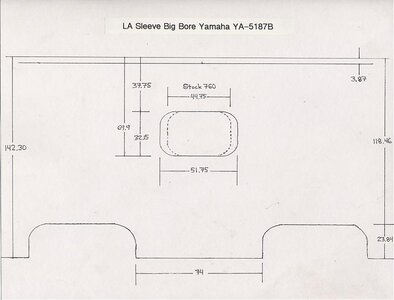

I'm building a few big bore engines right now, so here's some good info. I purchased an old 760 cylinder off fleBay that was all corroded and needed to be re-sleeved. When I removed the sleeves they had markings that said Los Angeles Sleeve Co. So I purchased some big bore sleeves from LA Sleeve part number YA-5187B from Jet-World for $86.50 each and to my surprise they are the same diameter, so they will drop right in with some heat applied to the cylinder. The only difference in the big bore sleeves is that the exhaust ports are a little wider and it will accept bore sizes up to 86.5mm because they are the same diameter all the way down to the bottom of the sleeve. I made the exhaust ports a little wider at 56mm because I wanted it to be 66% of the 85mm bore size for freestyle use and I'm going to install the sleeves about .020in lower by turning down the lip on the cylinder because they give you a little extra metal on the sleeve tops, so my port timing will be lower then the stock 64x. Also I trimmed the exhaust bracket mounting supports down to look more like a 61x cylinder and for use with the girdled head hardware. Now I just need to find some 10x1.25 to 8x1.25 stainless inserts for the b-pipe exhaust manifold to mount up. If you're going with the Kawasaki flat top pistons with the LA sleeves the exhaust ports are on the high side and the cylinder will have to be milled down which will make below-deck exhaust port even higher. If you were to mill the bottom of the cylinder it will lower the port timing but you may need to trim the bottom of the sleeves also. The Northwest sleeve would probably be a better choice for flat top piston use since the below-deck exhaust port timing is about the same as a 61x cylinder. Also the Kawasaki flat top pistons will need to have the skirts trimmed and the ring pins don't line up with the Yamaha sleeves. If you chamfer your auxiliary transfer port real well they can be used but you'll be taking a chance on snagging a ring. The Riva flat top pistons are almost the same as the discontinued R&D Dominator pistons and are still available. They have a nice ceramic coating on the top & bottom of the piston and are well worth the additional money. They can be purchased at AJS cheaper then what Riva sells them for and they come with the upper bearing.

Attachments

I was told otherwise about the NW sleeves. I was told they come preported too high and that the lasleeves come with stock 61x timing as im now seeing isnt true. I guess i could machine it off the bottom rather than the top but i could also just send the sleeves back. LA ripped me off at 250sumthin for both when they are cheap at jet-world. I got the kawi pistons cause i could get them brand new for 75 bux each.

Do you have any dimensions like that for the NW sleeves? I want to do this once and do it right.

Do you have any dimensions like that for the NW sleeves? I want to do this once and do it right.

Last edited:

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

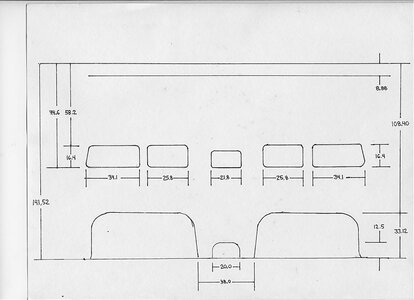

The flat top pistons are about 3.88mm lower then the standard dome top pistons. This all needs to be calculated with you port timing, duration, piston squish, dome choice, stroke, etc when building your engine. The pictures from right to left are, standard dome top Wiseco, Kawasaki flat top, and the Riva flat top. Also here’s the port timing of the Northwest big bore sleeve part number 1588-B. You can take the aluminum off the top or bottom of the cylinder and install the sleeves at different heights to vary your port timing when building a flat top engine. Note that the northwest sleeves have a bigger flange at the top for adjusting the height variation in the cylinder.

Attachments

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

The LA big bore sleeve works perfect with the 62T 760 cylinder and the Northwest big bore sleeve works perfect with the 61x 701 cylinder. The below-deck exhaust port height on the NW sleeve is 39.75mm which is about the same as the 61x port height. The porting is like the R&D Dominator type sleeves which make this sleeve work for racing or freestyle depending on the height which it's installed and the piston flat top or dome top.I was told otherwise about the NW sleeves. I was told they come preported too high and that the lasleeves come with stock 61x timing as im now seeing isnt true. I guess i could machine it off the bottom rather than the top but i could also just send the sleeves back. LA ripped me off at 250sumthin for both when they are cheap at jet-world. I got the kawi pistons cause i could get them brand new for 75 bux each.

Do you have any dimensions like that for the NW sleeves? I want to do this once and do it right.

Attachments

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

I was trying to find some 10x1.25 to 8x1.25 stainless timeserts at McMaster Carr but only found the 10x1.25 to 6x1.0.#.0, if you're looking for stainless inserts, I've had good luck with stainless timeserts.

They seem to be too thick for the standard 8x1.25 exhaust bolt?

I'm thinking that a 10x1.25 to 8x1.25 16mm long helicoil would work well because it's thinner.

Where have you seen the 10x1.25 to 8x1.25 stainless timeserts?

www.timesert.com

Paul sells em, too.

You don't need the insertion tool, as the appropriate insert just threads right into the original threads without modification.

Paul sells em, too.

You don't need the insertion tool, as the appropriate insert just threads right into the original threads without modification.

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

Cool thanx. :biggthumpup:

You are a wealth of knowledge. I think im going to go with the NW sleeves now. I think they will be easier to make work in my application. I think ill just have the sleeve installed 3.88 mil lower than intended and have it decked flat with the sleeve. That should get me with 61x stock timing. Either that or have the LA sleeve installed 3.88+the 2.58 difference in the 61x to 62t exhaust height. But that could make the transfers somewhere i dont want them. NW seems like the way to go. Ill measure the 61x stock sleeves tomorrow and run teh math to see what i need to do to get them where i want them. I couldnt find any numbers like what you have on those diagrams so i didnt know which one to go with.

Also anyone ever redrilled in new places for the ring pins? I was thinking about maybe trying to relocate them to the right position. Wasnt sure if anyone has done this? Doesnt seem like it would take to much work.

Also anyone ever redrilled in new places for the ring pins? I was thinking about maybe trying to relocate them to the right position. Wasnt sure if anyone has done this? Doesnt seem like it would take to much work.

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

You will find that the Yamaha 701 61x has a below-deck exhaust port height of 39.6mm, with a width of 48mm. All the transfers are the same height - 55.4mm. The main transfer port width is 31.75mm, the auxiliary transfer is 25.4mm wide, and the boost port is 21mm wide.You are a wealth of knowledge. I think im going to go with the NW sleeves now. I think they will be easier to make work in my application. I think ill just have the sleeve installed 3.88 mil lower than intended and have it decked flat with the sleeve. That should get me with 61x stock timing. Either that or have the LA sleeve installed 3.88+the 2.58 difference in the 61x to 62t exhaust height. But that could make the transfers somewhere i dont want them. NW seems like the way to go. Ill measure the 61x stock sleeves tomorrow and run teh math to see what i need to do to get them where i want them. I couldnt find any numbers like what you have on those diagrams so i didnt know which one to go with.

Also anyone ever redrilled in new places for the ring pins? I was thinking about maybe trying to relocate them to the right position. Wasnt sure if anyone has done this? Doesnt seem like it would take to much work.

You will need a good condition un-ported 61x cylinder if you're going with the Northwest sleeves. The cylinder casing will need to be bored to 3.581" (0.005" of interference fit) with a 3.739" diameter counter bore, .375" deep. This will put your transfer port timing at right 59.40mm in the aluminum casting. Then mill .140" off the bottom which will put you transfer port timing right at 55.84mm. After the sleeves are installed you will need to partially assemble the engine with the pistons and the cylinder to measure your piston to deck height. You will need about .045" to .050" piston squish and you should only have to take off .025" to .035" off your top deck surface.

BTW Tim Judge is the one who told me to take off .140" or 3.57mm off the bottom of the cylinder with these northwest sleeves. This will retain very close to your 61x port timing when using the flat top pistons.

Also I found out that the Kawasaki flat tops have a two degree angle and the Riva flat tops are completely flat. If you're using the Riva 85.5mm 29cc flat top domes they have a one degree angle, so this may cause some problems with your squish band bending radius.

Paul at LPW can relocate those ring pins but it would probably be cheaper to buy the Riva flat tops. If you still want to use them I can make you a paper template of my Riva flat tops so you can trim the skirts if needed.

That is exactly what i was looking for for info :arms::arms:!!! If you could make a template of those riva ones id really appreciate it. Thats exactly what i think im going to do to it. I have a totally unmolested 61x cylinder sitting in the garage as a spare im going to do it to. I think i can move those ring pins myself. I got them so cheap its worth the effort.

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

Just PM me your address and I'll send you the template out tomorrow.

Did you mean the counter bore to a depth of .350"? The .375" puts the sleeve below the top deck and a mill of the .025" wont even mate them up.

sfab

X

- Location

- Canada, QC

Did you mean the counter bore to a depth of .350"? The .375" puts the sleeve below the top deck and a mill of the .025" wont even mate them up.

ive bored mine at .35" and it was almost flush. i have removed maybe a max of 0.01" of the top of the cylinder to make it perfectly flat.

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

After you bore the cylinder casting to 3.581" (0.005" of interference fit) you will find that the transfer ports have moved down to 59.40mm because of the roof angle. If you were to install the sleeves at a depth of .390 they would come out exactly aligned with the transfer port roof and sleeve angle. The .375" measurement will allow the use of the stock base gasket and you will only have to mill the cylinder top aluminum .025" to .035" to get your piston squish clearance right. You could sink the sleeves down to .390 and use a thicker .020" base gasket but this would raise the exhaust port top deck height and you would have to mill the cylinder top another .020" added to the .025" to .035"Did you mean the counter bore to a depth of .350"? The .375" puts the sleeve below the top deck and a mill of the .025" wont even mate them up.