- Location

- Jackson MI

i ended up doing that inbetween layers of glass. Worked out well.

Well, today was a rough day.

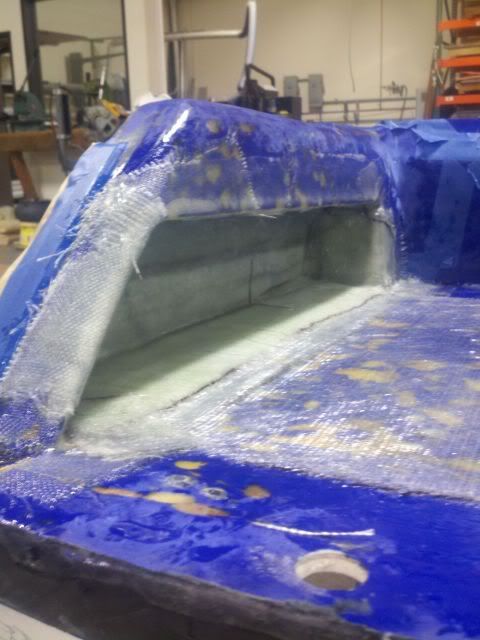

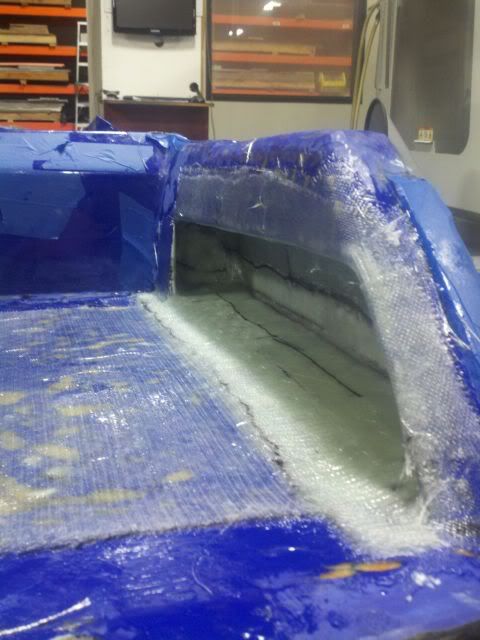

Since I had to wait to swap out resins, i figured i'd work on the footholds and get the left one glassed in with 8 layers of 10oz cloth. Was all going well till I found out that our 10 yards of cloth wasn't enough to complete even the single foothold. I spend a decent amount of time shaving the foothold to a SMOTH finish.

I also spend forever and a half preparing the the inside of the hull for layup along with creating a template to account for yamahas plethora of inserts on the bottom of the hull. Should be interesting trying to get all these cuts in the carbon cloth. EEEK.

can also use filler before laying glass, get it to the point of perfection you're happy with.

i do agree on letting the resin get tacky before getting the glass on there. will allow for a better bond.

when you're done with yours, come help with mine.

Looks really good so far Kurt. I would run the foot holds as far back as possible though. The whole point of a tray length foothold is that you can lock your foot in any where in the tray.

oh man, that must have been a b*tch to get off your hands. ski looks good, nice work.

FYI, a $2 bottle of rubbing alcohol cleans up 5200 real quick.

Keep up the good work!