OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

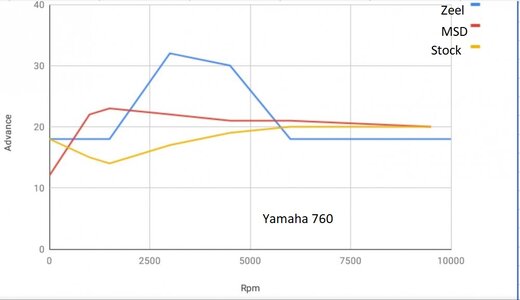

I can't count how many times I've been asked to map out the OEM 64X Timing curve but it's finally done!

It's not what I expected but honestly, I have absolutely no experience with the 760 based skis so I can't say it's good or bad, I just didn't expect the peak timing to occur so late in the RPM range.

If anyone has experience, please feel free to challenge my results. My test bench is improving with each use but it still does have certain flaws.

In this case, I was first able to mock up and test the full range of accuracy using a Zeeltronics GP760 ignition so I am fairly confident in my results. My measured results matched up to within half a degree from 800 RPM, right up to 6000 RPM where the timing light cuts out.

It's now been requested that I compare to the MSD curve but I do not own or have access to one so if you want it mapped, somebody will have to send one in.

It's not what I expected but honestly, I have absolutely no experience with the 760 based skis so I can't say it's good or bad, I just didn't expect the peak timing to occur so late in the RPM range.

If anyone has experience, please feel free to challenge my results. My test bench is improving with each use but it still does have certain flaws.

In this case, I was first able to mock up and test the full range of accuracy using a Zeeltronics GP760 ignition so I am fairly confident in my results. My measured results matched up to within half a degree from 800 RPM, right up to 6000 RPM where the timing light cuts out.

It's now been requested that I compare to the MSD curve but I do not own or have access to one so if you want it mapped, somebody will have to send one in.

Last edited: