I'm a hack and I'm going to answer you as a hack. I'm not sure about your budget situation since you have no problem throwing away hulls. It would be easy to drop $1-2k in materials to build 1 hull so the idea of that being disposable is a bit outside of the realm of the methods I am willing to invest in but it will be from the perspective of top notch hack work.

There are a lot of factors to 3D printing. The most common method is FDM printing. The first thing to note about 3D printing is that it isn't really 3D. Its better described as 2.5D printing. It is 2D layers stacked to make a 3D object. Why is this an important distinction? Because 3D printing is pretty strong on the 2D X/y Axis, but it is pretty weak in the Z axis. Parts are very likely to delaminate under any amount of force and fail. I couldn't imagine printing a real working hull with FDM printing.

There are ways to manage delamination failures. I commonly use assemblies to keep my hobby parts together. For example, if making an airbox, they usually fail from delamination. The print can usually handle compressive loads but not tensile loads. However, look at a Superjet motor with a Girlded head. It changes the cylinder from tensile to compressive loads. This same thing applied to an airbox saves the 3D print. 3D print a patten for a top and bottom girdle (cut from lexan or aluminum), then compress your desired flow path between these pieces, which creates strength in an assembly, if that makes sense.

This method works because the part has a flat top and bottom. A hull is much more complexed in design, so this method is harder to use. You could 3D print a shell, then fiberglass reinforce it. Bote Gatorshell paddleboards are just ABS coated fiberglass. However, the layup process is highly likely to result in significant heat warp and damage to the 3D print. I have never tried this, so I can't say that it wont work. I would imagine that the process could work, but would likely require a prohibitively thick print.

There are some additional considerations for 3D printing. The Creality CR10S5 has a 500^3 build volume and isn't inexpensive for a hobbyist despite being the cheapest large format printer available. A single part in this volume can take 3-4 Kg ($100) worth of filament and take a week to print. That's 20in^3. A hull could easily take a minimum of 8 prints, adding up to nearly $1000 and 2 continuous months of printing. The printer has filament run out detection, but I will point out the letting the filament run out has always resulted in a failed (misaligned or delaminated) print when it attempt to continue. This might be worth dealing with for a production quality plug where I am looking for perfection, but I can build a test plug (where perfection is not required) every bit this fast for much less cost using drywall and foam. I believe that a CNC Router cutting foam would be a better investment, and don't forget, you can cut the foam short, coat it something hard and run it again, for a harder finish than foam. This is how some of the the big boys build boats.

Now, that's not to say that 3D printing is not a viable option for hull building, and I have dabbled in some of these methods.

The BabyJet was hand built and any tools I used were hand made. This was quite the cumbersome process. It's all documented here...

We are about to embark on an amazing adventure to waste an absurd amount of time and money to introduce a little lady into a sport she can't even yet comprehend... Initial measurements and sketches were taken from her walker onto PEG board. The wheels for this were salvaged from a jogging stroller.

www.x-h2o.com

Wooden tooling sucks....

View attachment 440422

Since then, i have began using my 3D printer for these jobs which much faster are more precise results....

View attachment 440423

View attachment 440425

View attachment 440424

This radius used to take days for me to shape by hand, but with the 3-printed tool, I completed this plug shape in an hour.

3D printing can be taken a step further and be used for plugs and molds. I have done neither, because my surface modeling skills are insufficient. However, I have practiced with the methods, just not with fiberglass composites.

I did however 3D print a mold for paper machete to teach my daughter about how her BabyJet was built.

View attachment 440426

View attachment 440427

View attachment 440428

So I do know these are viable methods for building boats. 3D printing the mold saves the work and materials of building a plug and building a composite mold. What I do not know however is the impact of heat on the mold, as I haven't use this method on a larger scale or with exothermic materials.

I have not yet reached the CAD skills to move to the next step, but I do want to share something about resources. I started this post by saying I am a hack because I am resource limited. However, the greatest resource to a hack is ingenuity and what we think we need vs what what we can achieve for less can be shocking...

This here is a 3D scan of my Kawasaki X2. The price? $25, using a gifted Xbox kinect sensor, a $25 USB adapter and free software.

View attachment 440429

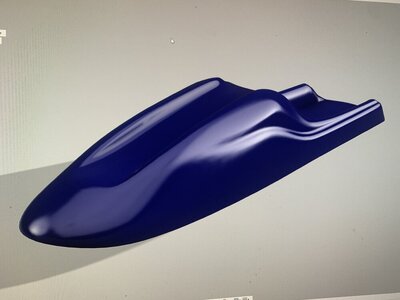

Imported into Fusion 360

View attachment 440430

This is my end point for Surface modeling. I probably have the skills after the modeling is done, but I can't move forward until I can learn to model better. Fusion 360 is free for hobby use. It is incredibly powerful. I use it for all my modeling for 3D printing, but it also includes G-code outputs for 3-axis CNC machining if you go the router route.

View attachment 440431

The hardest part of all this is figuring out the steps from start to finish (evolution of skills and equipment) and I got stuck on surface modeling. However, since then, I have realized that the solution is a hybrid plug process, where I print complexed parts of the plug, such as the hood seal and hinge assembly, while leaving the rest of the boat for more traditional methods, such as pump tunnel splashes and printed tools for chines / bondline shaping, until i am ready to move to the final step of fully 3-d printed (probably CNC routered, actually) plugs.

I hope this post answers most of your questions. Best of luck.