- Location

- jersey shore

my rickter fs2 has coremat in sides and tray that i know not sure where else

my rickter fs2 has coremat in sides and tray that i know not sure where else

Save the coremat for the mold. It's mainly used to build up the laminate quicker and print control.

Although it stiffens the part and keeps some of the weight down; no way I'd use it on the bottom. Just not worth it.

The tray area and sides would be about the only place.

You animal! :bigok:

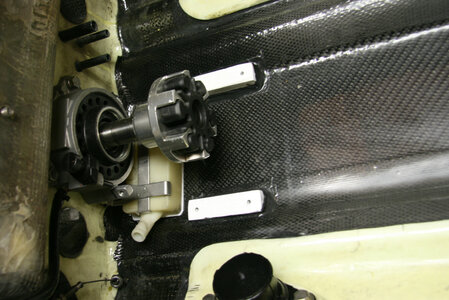

This is impressive.

How long did the layup process take you?

Is the plug pretty much a one-time use part?

This thread is giving me nightmares. The smell of Styrene perm imbedded in your skin yet? Great progress Roo!

make sure you brace the on the exterior of the mold before separating the plug from the mold so that the integrity of the mold is not compromised. great work though that plug looked amazing the mold should turn out really good

Now that is nice. When you going to need some help?

I have 10 days off here soon.

you definitely need a helper, or 3. layer after layer it gets worse the longer you do it. a little alcohol helps. not be be a prick but you realize you are not even half way thru? get help now!! more help means you cut down layup time. imagine hitting that hull for 30-40 minutes vs 5 hours??? at a point though when we were doing my mold I would just walk by and lay up on it and walk away. and any chance I had I would prep the material and just keep mixing up resin and laying up as I had a second. much easier to do it hit and run style.

lookin great! when you figure out what you may want for the hull if/when you are done with it lemme know, i could deal with riding a heavy ski.

Working the 29,30,31 on nights then i have 3 days off. Go to work on the 4th and then i have the next 10 off. So from the 5th to the 14th. Give me a call and put me to work! LOL.