steve-uk

Manners cost nothing

- Location

- Barrie - ontario

this is an awesome thread

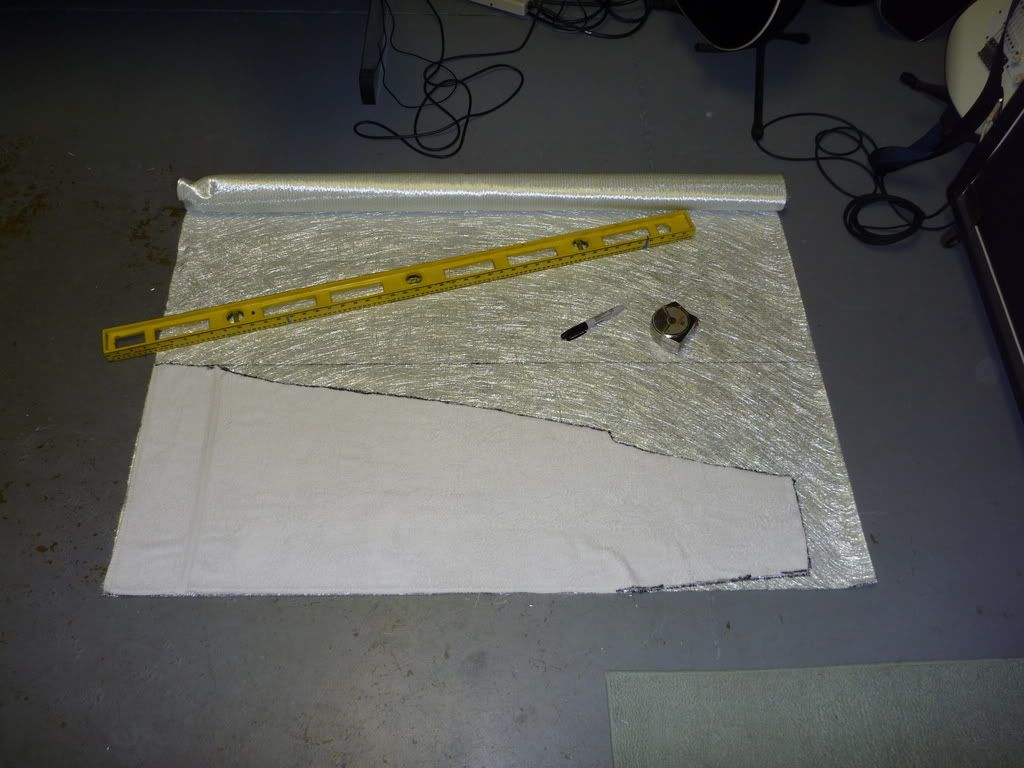

Hey, how did it turn out? Curious cause im about to get into the same thing. Did you use everything that is showed in the picture. Meaning was that enough resin etc, or way too much. Also how much Biax did you buy? The reason i ask is because im planning on doing my SJ (plus trey) and my B1 at the same time. Just trying to get a feel for what i will and wont need.

I know this is old but I was watching HD TV:Boston Whaler.

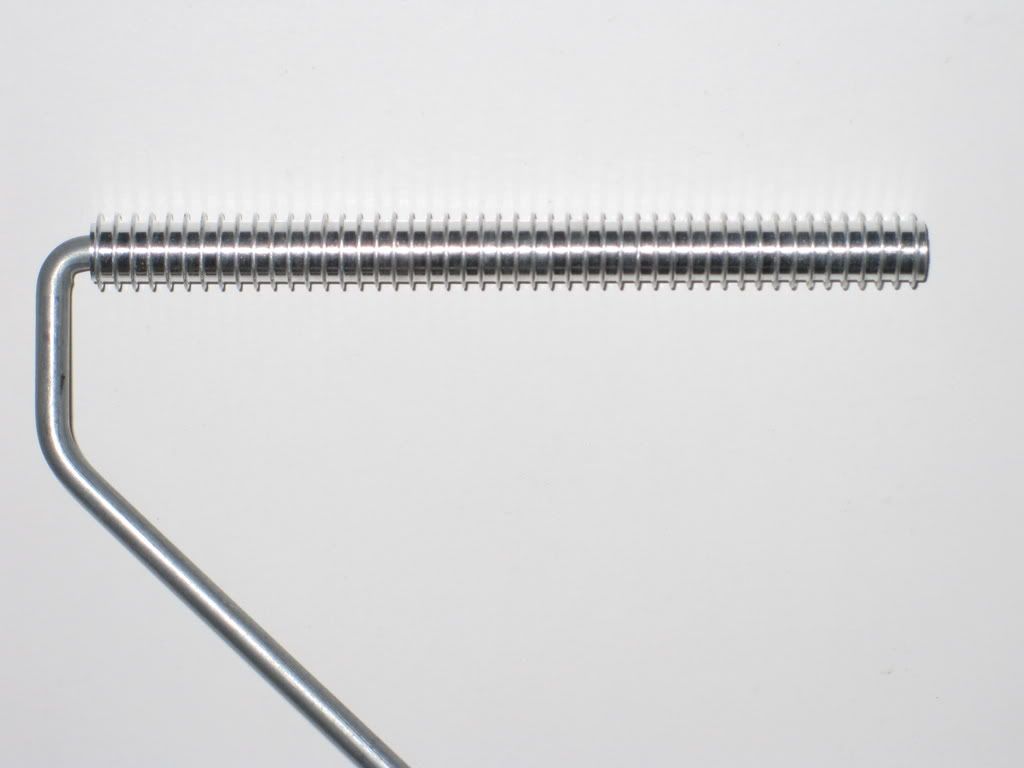

They use the mat in between glass and they use actual rollers to roll resin....not that thing ^^^ up there.

It was pretty cool watching it.....chopper guns and technique and stuff.

If you know a little before watching it you can pick up a lot.....and quickly.

this is an awesome thread

That roller will work just fine.... It might be a bit on the long side.

I use a roller just like that (3" version) for large spans of glass. It works great because not only does it eliminate air bubbles, it spreads out the resin.

Glassing with a roller:

1.) wet your surface with epoxy before you lay down your glass. It doesn't have to be slathered on, just a light coat with a brush.

2.) lay your glass down and wet out the complicated areas first with a brush (curves etc.)

3.) Wet out your cloth with a brush, I prefer to dunk the brush, brush the resin on an area, then dab with the brush to get the resin to soak in.

4.) Use the roller to spread out the resin and wet out the rest of the cloth. If done properly you should be able to wet out all of your glass with no excess resin pooled on top of the glass.

5.) Any areas that are still dry, dab some resin on with a brush and roll it into the glass with the roller.

Those rollers work great in my opinion, but are really only needed for large areas.

I was by no means criticizing, just adding some info for future reference.

I would say you did perfect. its always trial and error the first time. but look at all the products you used and pulled it off without a hitch!

This I why I asked about he 4:1, thats a bit much for a beginner.

Did you already trim this down? We usually use a bone-saw or just a saw blade to make it flush with the hull, then sand it real nice and smooth. Your work looks awesome Benny.