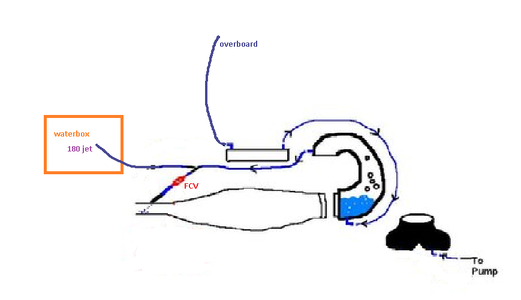

I'd close that bottom screw , completely, and then just make your adjustments on the top screw as needed. You can't get to that bottom screw anyways with the doghouse on. 180 is a good starting point. You may be able to choke it down some more during winter months. Just keep an eye on waterbox temps as the water gets warmer. It goes without saying that with a carbon waterbox, you want to stay on the safe (cool) side. BTW, do you have underpadding under that box? I can't tell.

When I ran my factory pipe I actually plumbed into the aluminum tube coming off of the stinger, as I wanted to keep the hose going into my waterbox from melting.

And, yes, I run a FCV.

I see your chamber is not supported. How long have you been running it like that? You may want to figure out a mount to the flywheel cover to prolong coupler life.