- Location

- NYC/Long Island

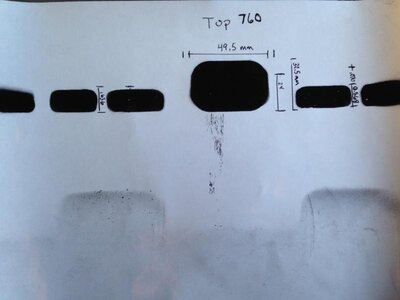

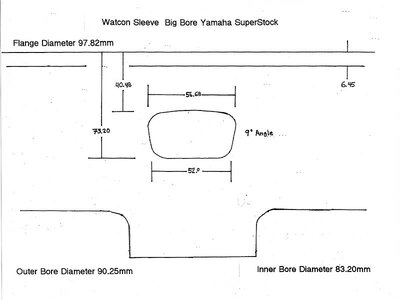

I read some post while googling a while ago that listed all the oem port timing/duration by degrees of rotation rather than from the top of the deck. Measuring from the top of the deck doesn't say much if it has ever been cut before. Also you can work your number closer to a 61x cylinder so you can get a accurate idea of what kind of powerband you will be obtaining. You can try find it, the name of the threas was port timing and duration. That 760 cylinder works good because its a larger sleeve and stronger casting overall. Cheap big bore