You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lowering a stock hood

- Thread starter needaride701

- Start date

WAB

salty nuts

- Location

- coastal GA

Believe he layed it over pieces of cardboard in the gap, then filled in low spots with filler once it hardened.

No matter what, there's lots of finish work to make it look that good when done.

Use your imagination

No matter what, there's lots of finish work to make it look that good when done.

Use your imagination

G

Goose

Guest

what i did was cut a v out of the hood horizontaly i started 1/2in down from the highest point in the front and marked it.then i went down 2 1/2 in and made another mark.make a cut twards the back and taper them down till they touch.then take and pull the top down and clamp it togather and lay glass over the gaps.i used the bondo stranded glass stuff in a can like bondo to fill in the voids and sand.hope that helps if i had pics it would make more sense.im working on another and will take pics along the way.ill be starting sat

i work with 17oz biax so i can just lay it over or under and keep a similar contour no problem. Another method i have used in the past is getting real thin sheet metal and using it to fill voids while glassing and making the contours flow smoothly. Either way it takes some time and shaping.

- Location

- Long Beach, CA

it's pretty easy, I did my SXR. Use masking tape, find a nice looking angle and grap a circular saw and don't think twice. I chopped quite a bit off the SXR hood and rounded the nose. it takes patience and fiberglass and patience. On the SXR you just use a set of Blowsion hood hooks and mount them on the bottom side of the pole bracket, it locates the hood hooks 3/4" lower.On the hood you need to remove the hooks and install them using the top hole on the bottom stud and then drill a new bottom hole and insert a new bolt and nut.

thegoldenboy

RN Surgery... soon

- Location

- Toronto

I lowered my squarenose hood. Its finished, I just need to get pics up and into a thread. Stay tuned. I did it the same way as a pic above.

Cut tops off, foamed, glass, fairing compound for aesthetics, paint.

Cut tops off, foamed, glass, fairing compound for aesthetics, paint.

- Location

- Melbourne, FL

I did a little more than just lowering mine, but the concept is the same. I used styrofoam and shaped it with a drywall rasp and sandpaper. I filled in imperfections with spackling compound and then glassed over the foam with SOLVENT FREE epoxy resin. You will be in for hours and hours of finish work to make it look good.

Attachments

So after you cut the top off of hood do you obviously cant just bridge the void with glass...how do you get the contour on top?

I'm in the middle of doing this now. I made a foam nose piece a bit smaller than the end product and then brushed resin over the top. I'll use something like bondo that doesn't sand away as fast as foam so I can get a nice symmetrical nose. Once this is done, I'll put a pole on and the hood and use both the pole and nose piece to get the angles correct.

I plan to fill the upper voids of the hood (the bits that you are cutting off) with foam, and shaping that until it's the right shape. From there, I'll coat with resin, or something nice and shiny, lay some glass over the top of it so I have a negative of my profile shape. Then, flip the hood over, dig out all your foam and pop the top mould out. Wax up the mold, sitck it back on top, and then fill/glass underneath. If everything is a bit lower than your desired profile, you can use bondo to fill and get it right!

I am also lowering my hood.I cut the top of the hood,the fire ext. tray ant the pad for the pole off. The pad was first,that way the pole would sit down on the hood.Then just marked and cut.

I filled mine with great stuff and sanded close as I could to the desired shape.Now I have put a thin coat of bondo to get it even closer.

This is where I am at the moment.The next thing I will do is lay a light weight piece of glass over the bondo and then remove the great stuff and bondo.

I will run tape on top of the bondo so the glass will not stick.

Then lay glass on the inside for strength.

I hope it works out.

First time I have ever tried this.

I filled mine with great stuff and sanded close as I could to the desired shape.Now I have put a thin coat of bondo to get it even closer.

This is where I am at the moment.The next thing I will do is lay a light weight piece of glass over the bondo and then remove the great stuff and bondo.

I will run tape on top of the bondo so the glass will not stick.

Then lay glass on the inside for strength.

I hope it works out.

First time I have ever tried this.

i lowered my sn hood, would pics of that help, i took pics the whole way throught.....

pics would be awesome!!!!!:biggthumpup:

Frosty

New York Crew

- Location

- Western New York

soon to do the same, do you guys keep the liner or take it out and make a new mold?

take it out and make your own...

Attachments

Zeon

WNY Crew

- Location

- Buffalo, NY/ Crystal beach, Ontario

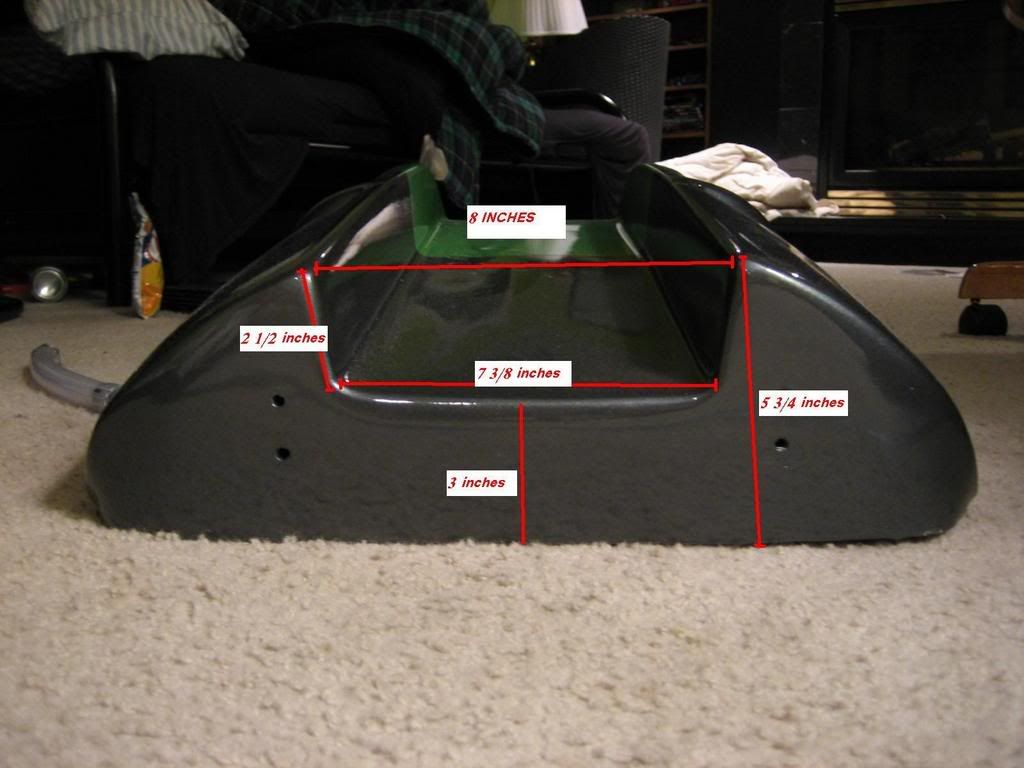

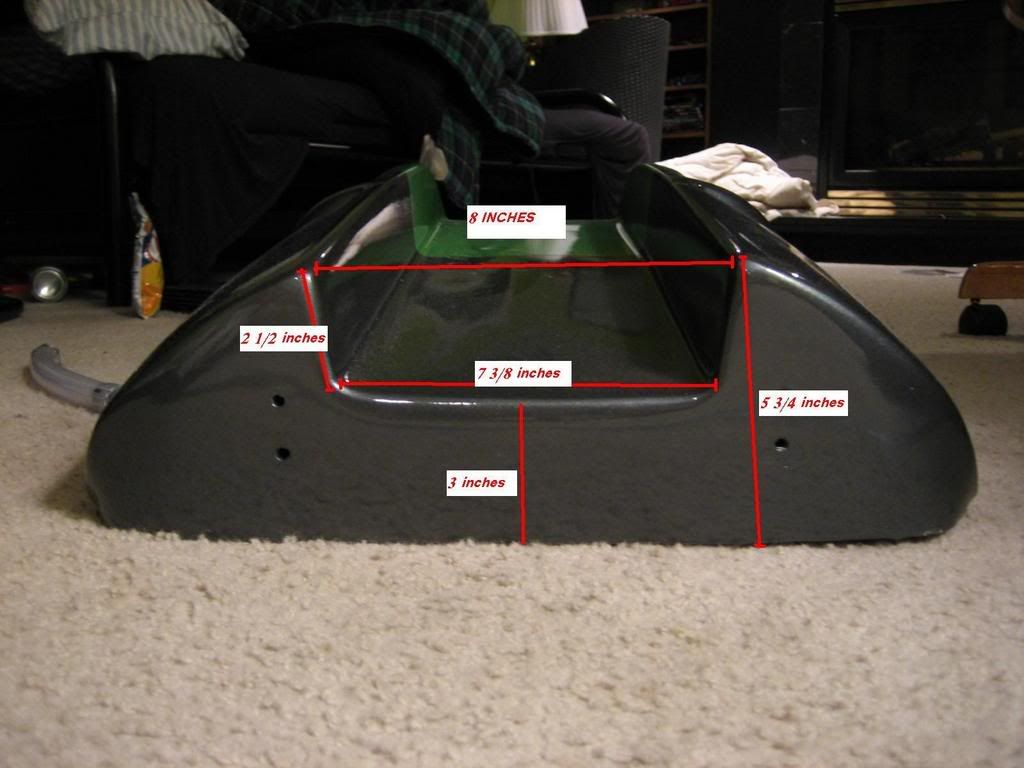

here you guys go for a little help on schematics... this is an aftermarket lowered hood but this can give you some rough est....

Superjet3

Waterlogged

- Location

- Jersey Shore

Zeon

WNY Crew

- Location

- Buffalo, NY/ Crystal beach, Ontario

Here are some pics of a stock hood that I lowered.

is that a bass boat?

randalj1

F.F.L.F. is why im here

- Location

- Chisago City, MN

For the guys that did the lowered stock hood, do you cut out the extinguisher compartment and make it flush? Where have you relocated the extinguisher?

Frosty

New York Crew

- Location

- Western New York

For the guys that did the lowered stock hood, do you cut out the extinguisher compartment and make it flush? Where have you relocated the extinguisher?

i'm leaving mine in... and will work around it.

FL-cracker

X-H2O

- Location

- old exit 72 Melbourne

Here are some pics of a stock hood that I lowered.

Damn Ihop! Nice work, and that paint is bad arse!!!! :Banane35:

Superjet3

Waterlogged

- Location

- Jersey Shore

Thanks, That was actually my white boat before i painted it white.. It was a pain to sand it all off.