WFO Speedracer

A lifetime ban is like a lifetime warranty !

- Location

- Alabama

I am Making a tubbie for the other side of the 300SX and I thought I would do a detailed thread start to finish so you can see the process involved.

A couple of things , this is how I do it, how you do it or most likely how you think you would do it may be different, I am doing it this way , take it or leave it , and last but not least all the I would do it this way comments, I don't need them save them for another thread.

With that out of the way I need a mold, well I don't because I have one but you would need one for sure.

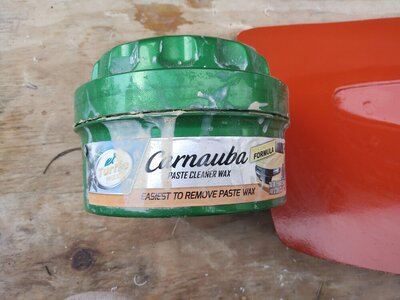

Make sure it's spotlessly clean , that means no traces of any resin or PVA left on the mold, clean it with acetone and make sure everything from the last tubbie is long gone.

A couple of things , this is how I do it, how you do it or most likely how you think you would do it may be different, I am doing it this way , take it or leave it , and last but not least all the I would do it this way comments, I don't need them save them for another thread.

With that out of the way I need a mold, well I don't because I have one but you would need one for sure.

Make sure it's spotlessly clean , that means no traces of any resin or PVA left on the mold, clean it with acetone and make sure everything from the last tubbie is long gone.