- Location

- Cheney lake Kansas

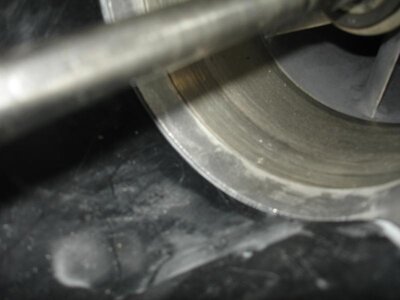

I would line the shoe up where you think it goes , but dont secure it with glue.. you could temporarly use the screws to hold it in place . but make sure your pump lines up with your pump shoe before you drill your holes to mount youur pump. basically mock it all up before you glue !