- Location

- South Florida

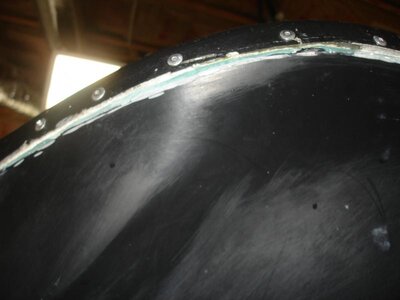

More pictures.

Attachments

-

DSC00125.jpg62 KB · Views: 38

DSC00125.jpg62 KB · Views: 38 -

DSC00129.jpg68.8 KB · Views: 43

DSC00129.jpg68.8 KB · Views: 43 -

DSC00131.jpg41.8 KB · Views: 41

DSC00131.jpg41.8 KB · Views: 41 -

DSC00136.jpg68.3 KB · Views: 44

DSC00136.jpg68.3 KB · Views: 44 -

DSC00133.jpg33.4 KB · Views: 27

DSC00133.jpg33.4 KB · Views: 27 -

DSC00130.jpg71 KB · Views: 33

DSC00130.jpg71 KB · Views: 33 -

DSC00134.jpg21.8 KB · Views: 41

DSC00134.jpg21.8 KB · Views: 41 -

DSC00135.jpg29.3 KB · Views: 34

DSC00135.jpg29.3 KB · Views: 34 -

DSC00126.jpg81.1 KB · Views: 42

DSC00126.jpg81.1 KB · Views: 42 -

DSC00132.jpg36.5 KB · Views: 32

DSC00132.jpg36.5 KB · Views: 32