freestylegeek

waiting...

- Location

- Grand Rapids, MI

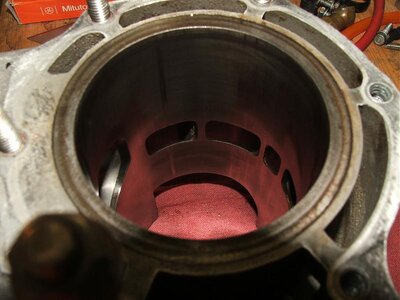

Wow, that's some thin cases! I think you should add some kind of aluminium plate there. I added a 1 inch think T6 aluminium plate to the bottom of my cases to accomodate the 10mm. the machining went right thru the cases and into the plate. but it is leak proof! now:woot:

I'm ready for 12MM!!:brap:

It's interesting you say that Steve. Paul and I were contemplating doing that, but since it's "only" an 8mm stroker, we didn't see the need. I'm pretty much planning on the aluminum plate for any stroker motor I build in the future.