You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Phantom Resurrection

- Thread starter mikesx

- Start date

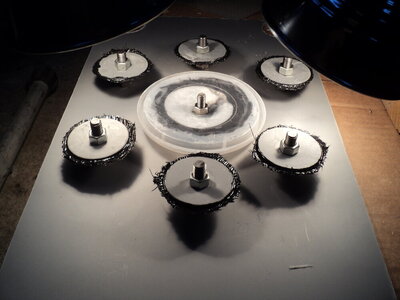

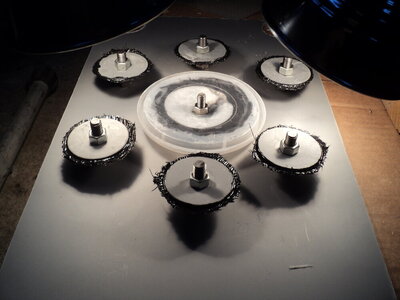

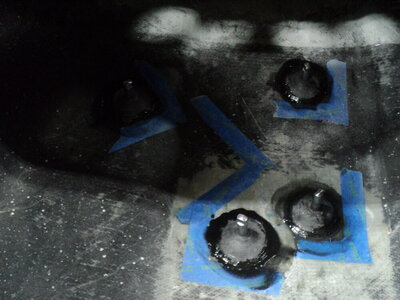

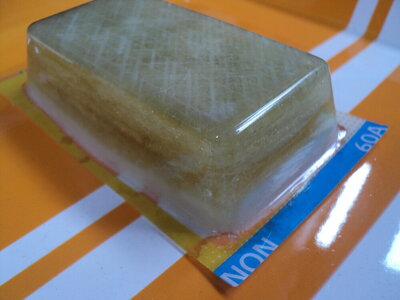

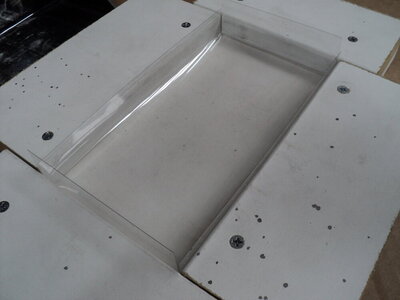

This is what I did for new inserts. I decided to use M10 Rotolocs, yes big manly M10's, if I need a smaller bolt EZ Lock makes a M10 to M6 adapter. I used dished washers to make covers for the epoxy and to press in place. I made placement studs out of 3/8 bolts, M10 and 3/8 are just about identical thread.