- Location

- New Mexico

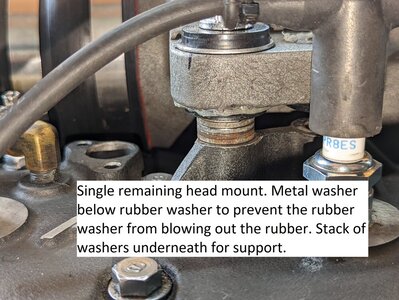

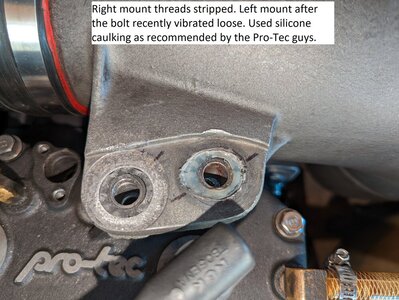

Picked up a 1990 SN Superjet recently and am looking for some recommendations. I believe the engine is a 701 ported to 750 with 135 psi compression on each cylinder. It has the Pro-Tec exhaust with the 4 mount points on the exhaust body. One of the mount points on the engine head is stripped and the other one has some play in it but still holds a bolt with red loctite. I just replaced the starter and in the process worked on the exhaust as well replacing the gaskets, worn water lines, JB weld to fill in damaged metal, new rubber grommets and rubber washers from Pro-Tec. The 3 exhaust body attachment points were torqued till the rubber started to “blow out” the sides. If I go tighter it will probably destroy the rubber. Had the ski out yesterday for a short 20 minute ride and the exhaust body vibrated the single bolt attachment left out. The previous owner just had two bolts in the exhaust body (one on the head one on the engine manifold to exhaust body) to hold it to the engine and they came loose after the first couple of rides with only the rubber wheel insert for vibration reduction (the rubber was mostly useless and worn down. It feels like these rubber inserts and washers are going to continue to just vibrate loose even with red loctite. I could cut off the head of a bolt, insert it into the stripped head attachment, JB weld it in and put a nut on it to get two head attachments again or maybe a Heli-Coil thread insert. I could just drop the rubber washer, use the rubber wheel inserts and just torque it down but then I might risk cracking mount points. I’m wondering if I shouldn’t just abandon this exhaust and pick up something else before it vibrates loose and breaks something else in the engine. What is an acceptable amount of vibration for an engine like this? I don’t see any issues visually with the engine mounts. If I did replace the exhaust is there another one that can handle the vibration? Do I need to worry about the metal shavings from the metal wearing down at the attachment points in the engine? I wipe it up and remove it where it has worn but I'm sure I don't get all of it.

TLDR: Pro-Tec exhaust vibrates itself loose. I have 3 of 4 attachment points in OK shape. I Could probably fix the 4th but it will still just vibrate until the mounts on the exhaust body break. Are my motor mounts going bad, causing the engine to vibrate too much? Is there another exhaust I can put on it that will handle the vibration? Am I doing something totally wrong? If I torque the bolts tighter than the rubber looks like it will fail.

Video link of the engine idling in slow motion:

A few pictures of my mounts attached.

TLDR: Pro-Tec exhaust vibrates itself loose. I have 3 of 4 attachment points in OK shape. I Could probably fix the 4th but it will still just vibrate until the mounts on the exhaust body break. Are my motor mounts going bad, causing the engine to vibrate too much? Is there another exhaust I can put on it that will handle the vibration? Am I doing something totally wrong? If I torque the bolts tighter than the rubber looks like it will fail.

Video link of the engine idling in slow motion:

A few pictures of my mounts attached.