Did anyone ever use one? I just went to use mine for the first time ever today and it does not want to thread in at all and I am not forcing it.

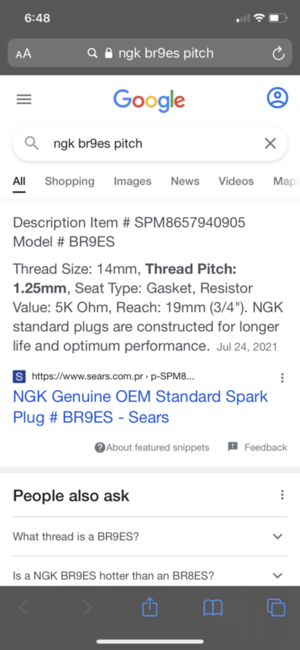

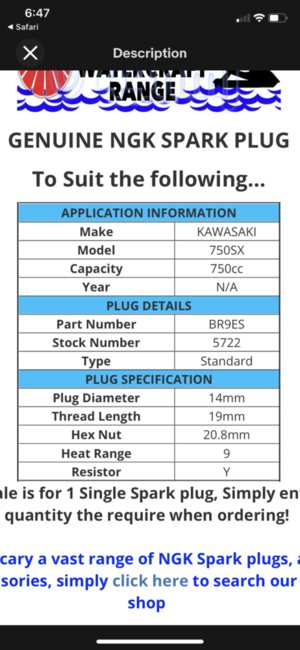

Are Kawi plug threads different than Yami? Is it possible he sent me the wrong one?

I definitely specified Yami.

Are Kawi plug threads different than Yami? Is it possible he sent me the wrong one?

I definitely specified Yami.