Myself

manic mechanic

- Location

- Twin Lakes AR

Oh my gosh......my size 13's would enjoy that!!

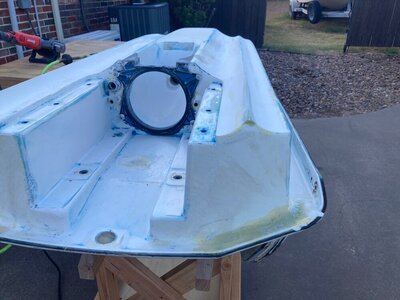

Glad I could help. I was in the same boat as you and tried really hard to find as much info as I could regarding the install. There's not much out there, sadly. To add to the above, if you use similar screw locations as me, #8 x 1.5" flat head stainless screws worked great. I found that the best way to not go too deep with the countersink was to bump it into the hole multiple times to keep track of how deep I was going. Even doing that I still broke through in a few spots. At that point all you can do is cuss and make new hole knowing you'll have to fill the busted one. Also, I forgot to add that I babysat each sponson for about an hour after screwing them down after applying the epoxy. As it cures it keeps spooging out of the edges and I kept wiping it off with my finger tip until it stopped. Should cut down on sanding in the long run.I want to personally thank you for the great photos and installation description.

I have two sets of Tom21 sponsons to install which I have had for a year.

Your thread will help.

I appreciate that compliment more than you know, thank you!Sweet build. Your work is as clean as your shop dude.

Sadly nothing worth reporting at the moment. I've been swamped at work and so has my wife. Add two kids in the mix and it has left zero time lately for me to make much progress. I WILL finish it... someday, lol.Any updates?