SpaceCowboy

breaking something

- Location

- Ypsilanti Michigan

Ok...had my buddy Corey out tonight to do some pole installation.

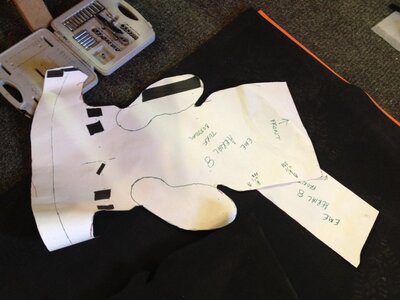

We mounted the base of the pole in first and marked where it was at the straight up position...then put the pole base in the down position and marked that. Then between those two lines we marked the 2 center holes for where the breather tubes are going to be installed.

EME's have the side plates so Corey's idea (and its worked before) was for the pole bolts to back up to the plate vs making a sandwich between the aluminum and carbon fiber. This will eliminate the frequency of having to re-tighten pole bolts.

drill holes!

cleaning up the edges and making the tube holes a little big bigger.

PVC...lightweight and perfect for this...also with some PVC glue and the next size diameter this will seal this tight to the hull.

The Blowsion pole tubes are slightly larger than these outlets...so I'm going to put them in the lathe and turn down the inside a bit so they will fit through.

When I get this all done I'll get a pic with the whole pole installed.

We mounted the base of the pole in first and marked where it was at the straight up position...then put the pole base in the down position and marked that. Then between those two lines we marked the 2 center holes for where the breather tubes are going to be installed.

EME's have the side plates so Corey's idea (and its worked before) was for the pole bolts to back up to the plate vs making a sandwich between the aluminum and carbon fiber. This will eliminate the frequency of having to re-tighten pole bolts.

drill holes!

cleaning up the edges and making the tube holes a little big bigger.

PVC...lightweight and perfect for this...also with some PVC glue and the next size diameter this will seal this tight to the hull.

The Blowsion pole tubes are slightly larger than these outlets...so I'm going to put them in the lathe and turn down the inside a bit so they will fit through.

When I get this all done I'll get a pic with the whole pole installed.