waxhead

wannabe backflipper

- Location

- gold coast

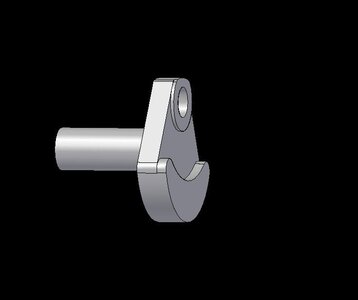

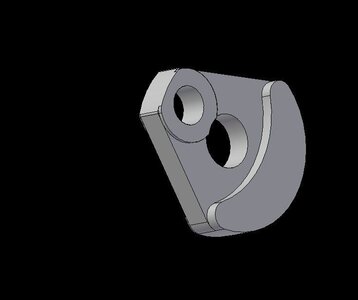

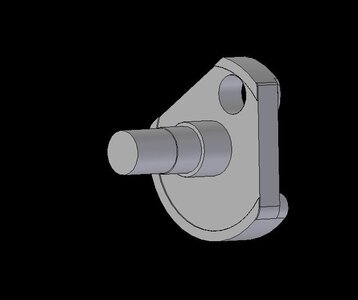

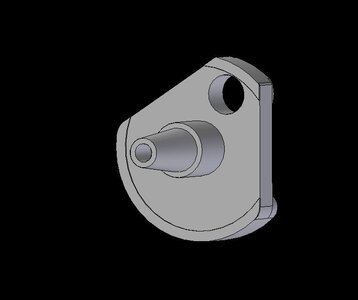

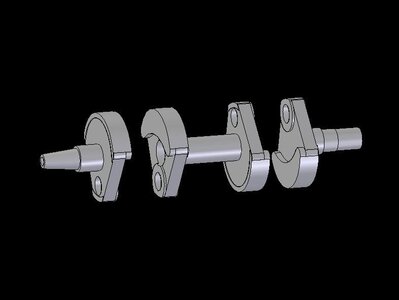

this is a 6 mil stroker crank

its about to get made out of wood to make sure its all ok

its alot cheaper that way

The plan is to make a 5 and a 6 the rods are to hard to get for a 8 mil

i will post pictures of the wooden one when i get it finished

its about to get made out of wood to make sure its all ok

its alot cheaper that way

The plan is to make a 5 and a 6 the rods are to hard to get for a 8 mil

i will post pictures of the wooden one when i get it finished

Attachments

Last edited: