- Location

- Tidewater, VA

After toiling with hammers, heat, impact hammer, wd40, PB, CLR, and cursing I found a way that might work consistently for others.

First, I removed the ebox from the bulkhead.

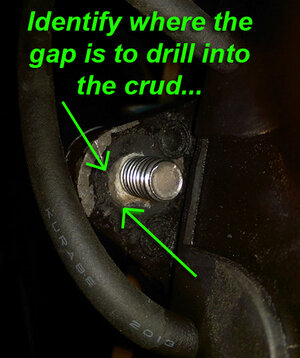

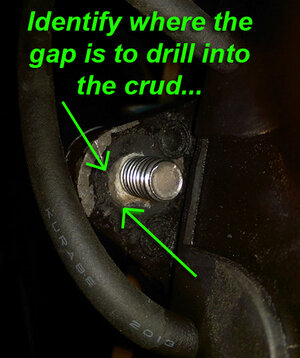

This is dark because I soaked it in everything I could think off to break it free/ dissolve the crud. but you can see the gap that's filled with the crud.

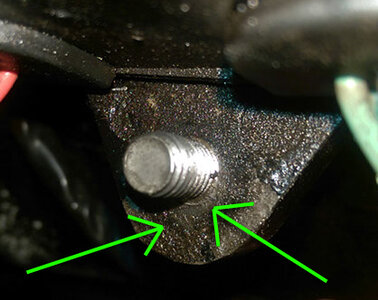

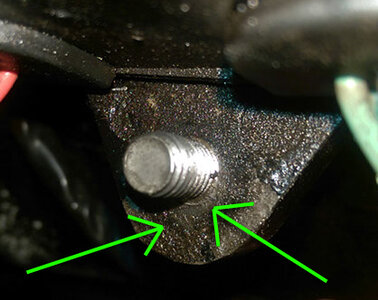

Once you find it get a 1/16" bit and drill one or two right next to the post. The crud is softer than the post and you barely damage the post. #winning

After drilling the holes you can hit the bracket in a way to twist the post and it breaks free pretty easily!!

Bracket free E-Box !!!!

I have chased the ebox holes with an 11/16th bit and I will get the cruddy brackets into the glass beader. When I reinstall I will wrap some teflon tape and a little graphite for next time.

Does this count as a tech post?

First, I removed the ebox from the bulkhead.

This is dark because I soaked it in everything I could think off to break it free/ dissolve the crud. but you can see the gap that's filled with the crud.

Once you find it get a 1/16" bit and drill one or two right next to the post. The crud is softer than the post and you barely damage the post. #winning

After drilling the holes you can hit the bracket in a way to twist the post and it breaks free pretty easily!!

Bracket free E-Box !!!!

I have chased the ebox holes with an 11/16th bit and I will get the cruddy brackets into the glass beader. When I reinstall I will wrap some teflon tape and a little graphite for next time.

Does this count as a tech post?

Last edited: